F52's smooth plastic wire design solves costly package puncturing

A food processor utilized a metal wire mesh belt for a slow-speed cooling tunnel that streamed water over hot aluminum cans of pie filling. However, when a new customer required the pie filling be put into plastic bags, the burr-riddled metal belt cut open 5% of the bags, spilling hot pie filling onto the belt, conveyor system, and floor. The processor lost valuable product and endured thirty minutes of additional cleaning for each shift (2 per day).

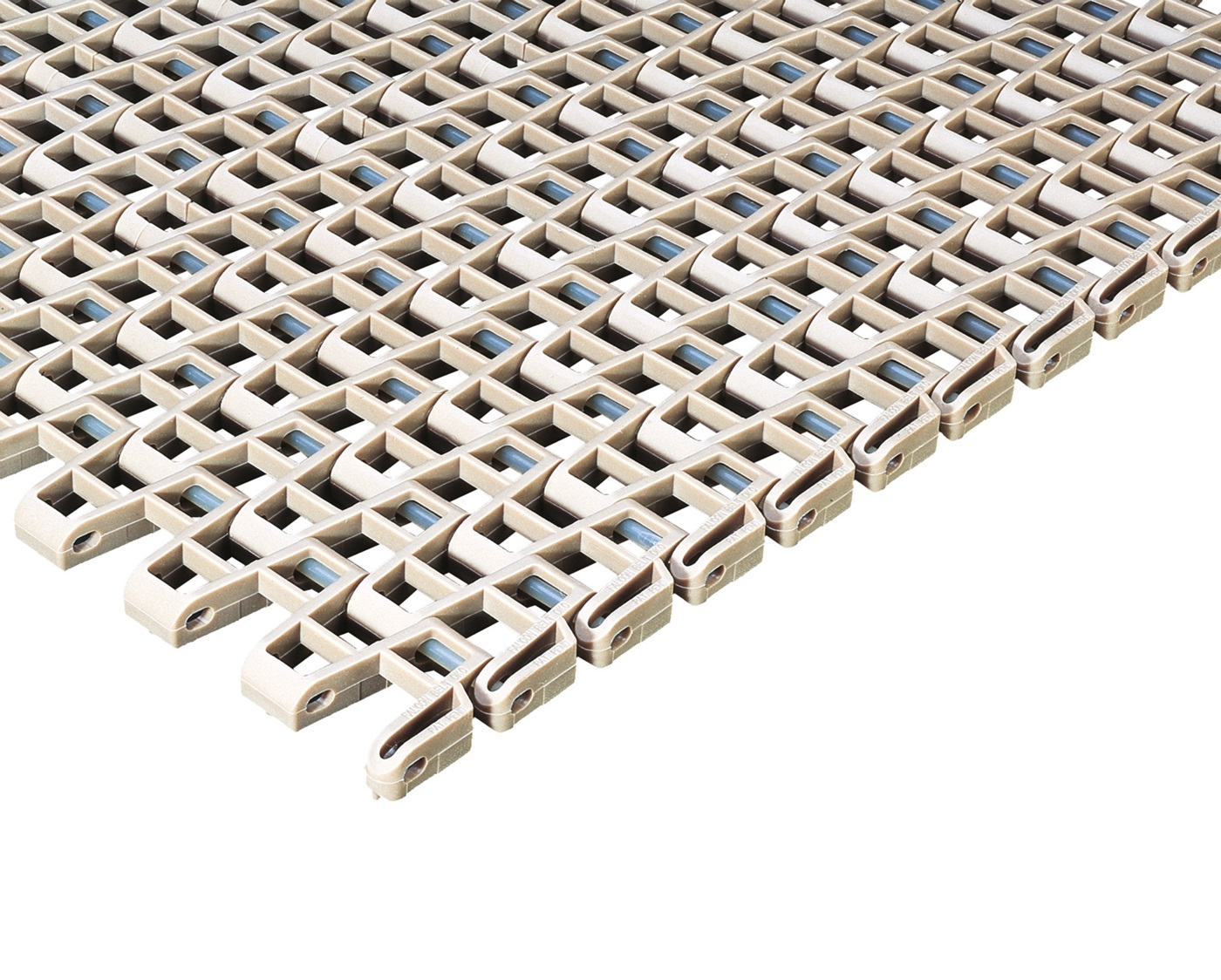

To solve the package puncturing problem, the customer required a belt with smooth, rounded edges and a material that resisted burring, ideally with a similar design to their metal wire mesh belt. Habasit satisfied this requirement with the Habasit F52, a flat wire style belt with smooth, rounded shapes for gentler handling than metal mesh belts. To handle the heavy load and high temperatures, Habasit offered stainless steel rods and a blue acetal material, which offers high strength and heat resistance.

Both a Habasit sales representative and application engineer collaborated with the customer on site to ensure all required system modifications were satisfied. After successful installation of the Habasit F52, the customer was able to switch freely between plastic bags and aluminum cans without any product loss or spillage in the cooling tunnel.

Overall, Habasit's engineering support and expert product selection yielded big results:

• Reduced annual sanitation labor by $4,920

• Eliminated product loss by $6,150 per year

• No need for additional conveying line for plastic bags

Total annual savings reached $11,070.