Habasit Introduces a Belt-friendly TPU Scraper Bar That's Tough on Residues and Better For Food Safety

Belt scrapers are essential on food processing lines for removing product residue from belt surfaces and maintaining hygienic conditions. But since scraper bars are frequently made of metal and hard plastic, they can damage the belt surface on contact, leading to cracks and scratches that are potential breeding grounds for bacteria and can compromise food safety standards. Damaged surfaces also reduce belt service life. Now Habasit can offer a superior alternative solution: a belt-friendly TPU scraper bar for fabric and monolithic belts. Efficient in the removal of product residue, TPU scraper bars ensure better hygiene, are safer for belt surfaces, and easier to clean.

Belt scrapers are used on food processing lines to meet several process challenges. With the introduction of its new TPU scraper bar, Habasit is further improving the benefits this essential component brings to food processors.

The primary function of the scraper is to remove waste and debris from the belt surface during production. When scraping is done correctly, the benefits range from improved operational efficiency to better hygiene and food safety. This is because material build-up can lead to a loss of sprocket engagement, or tracking issues from residue build-up on roller drums causing belt edge damage and increased motor wear and energy consumption. Poor scraping that leaves product residue on the belt can result in spillage and material accumulation on the return roller, posing a potential risk of bacterial growth and cross contamination.

Metal and hard plastic scrapers can damage belt surfaces

Because belt scrapers help to resolve so many issues, the food processing industry has put up for years with a major disadvantage of rigid metal and hard plastic scraper bars: the risk of damaging the belt surface. When cracked and scratched, the belt becomes harder to clean, and cracks can become a home for bacteria to grow. Furthermore, such damage reduces the self-cleaning effect of surfaces with excellent release. Belts may also need more frequent replacement, meaning additional costs for new belts and line stoppages.

Key advantages of flexible TPU scraper bars

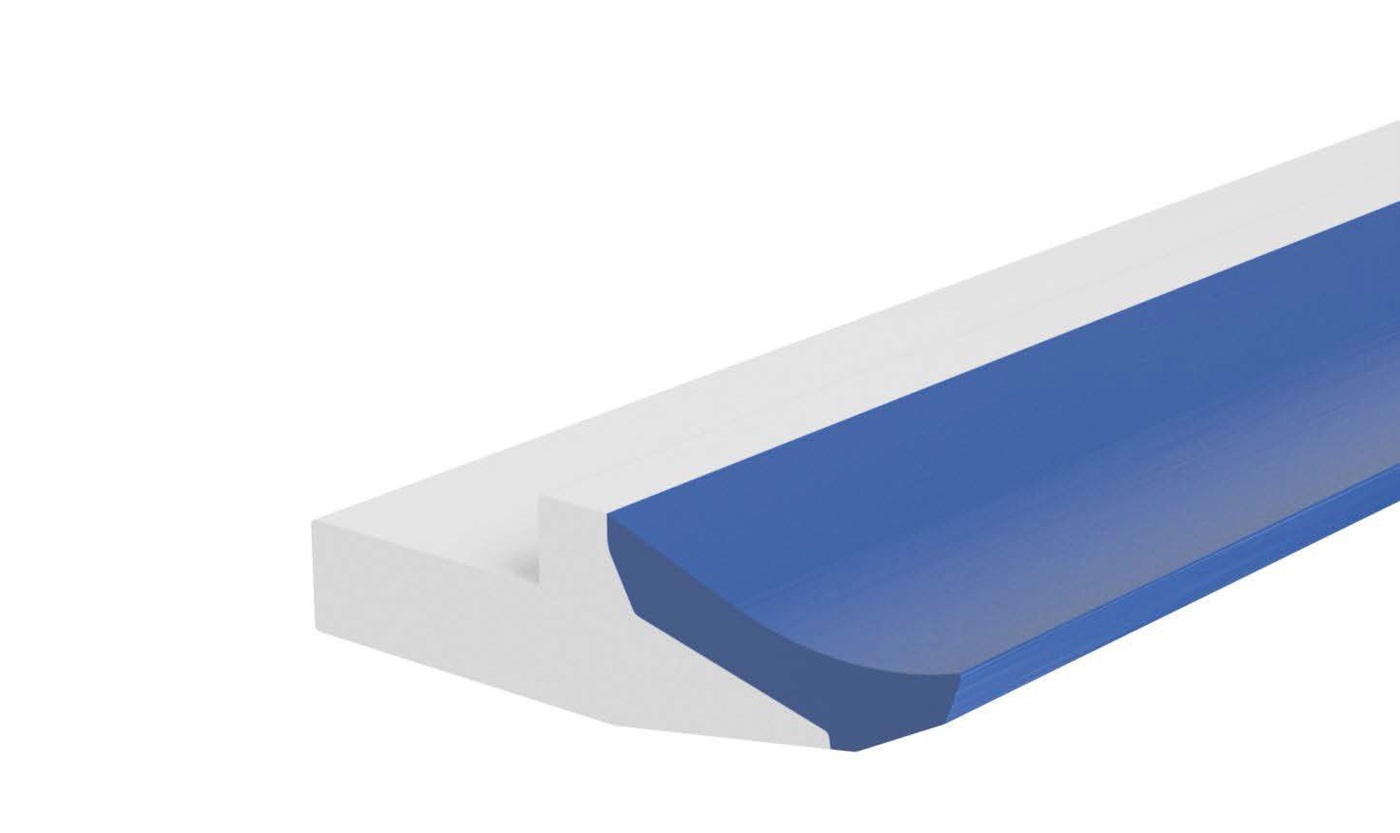

While classic belt scrapers are usually completely inflexible, the Habasit TPU scraper has the advantage of a flexible tip, which translates to three key advantages:

- No risk of damaging the belt surface - due to the reduced pressure applied between the scraping bar and the belt.

- More efficient cleaning - since the TPU scraping tip follows the belt surface at all times. The flexible tip also offers an advantage over metal or hard plastic scrapers mounted on a flexible rig, as rigid material on a tip lets belt irregularities push the scraping bar away from the roller, resulting in uneven cleaning.

- Easier cleaning – as liquids like oil, water and detergents are better dealt with by a flexible TPU scraper bar which maintains continuous contact with the belt surface.

Array of options available

Habasit's new belt scraper bars are available in TPU Polyester and TPU Polyether, with a range of tip hardnesses from 85 to 95 ShA. The TPU Polyether scraper bars are particularly suitable for applications involving higher temperatures and humidity, where hydrolysis resistance is required. The TPU scraper bars come in a standard 2.4 m length that can be adjusted to customer requirements. X-ray and metal detectable versions are available for additional food safety requirements. The TPU scraper bars are food-contact compliant and fulfill both EU and FDA requirements.