Strong belts for demanding applications

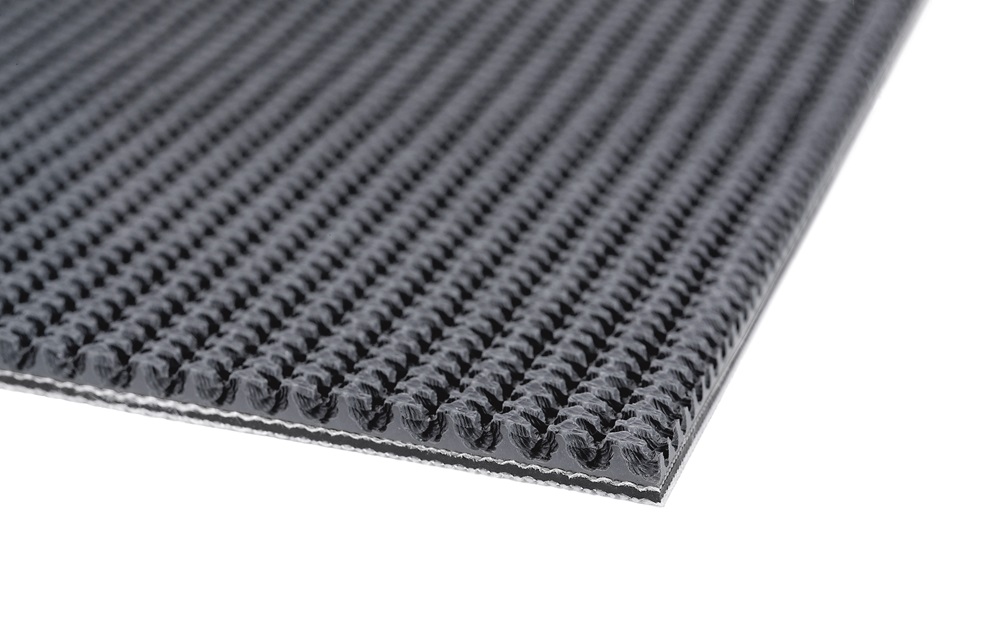

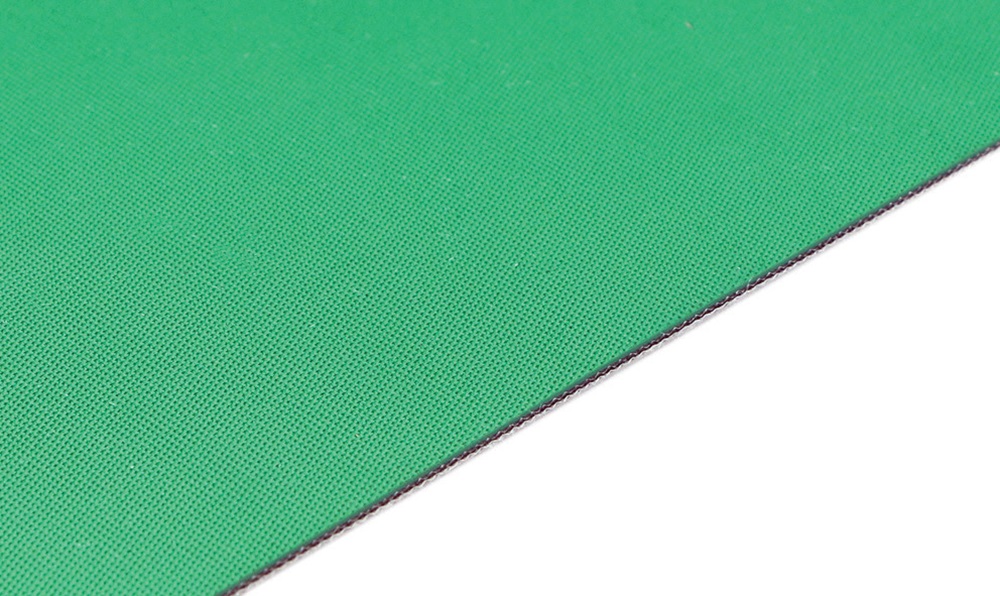

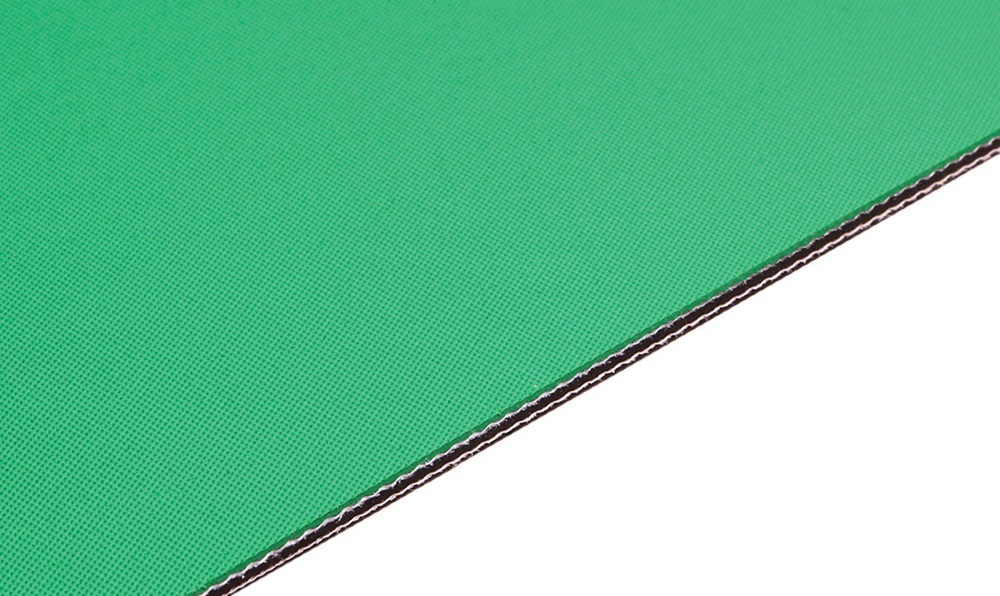

Habasit’s elastomer covered conveying and processing belts manufactured with NBR or EPDM rubber offer reliable and durable solutions for applications in demanding production processes and harsh environmental conditions.

The belts feature high abrasion- and temperature resistance, a consistent coefficient of friction, and a long belt life. Elastomer covered belts are suitable for a wide range of applications in various industries, including materials handling, paper manufacturing, paper and board converting, and packaging.

Browse the wide selection of Habasit belts, accessories and conveyor components

Industry solutions

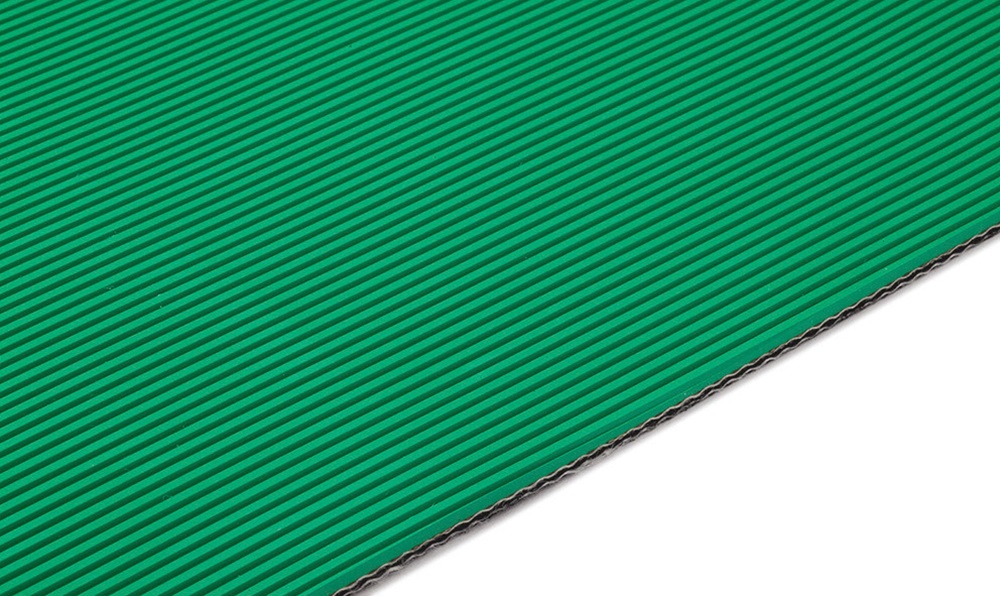

Materials handling and distribution centers

Transporting goods between production stages or to and from warehousing can offer a variety of challenges. Space is limited, so a high and consistent coefficient of friction not only guarantees smooth transport of all the different shaped and sized goods, but also reliably supports incline or decline applications.

High abrasion resistance

Robustness

Consistent coefficient of friction

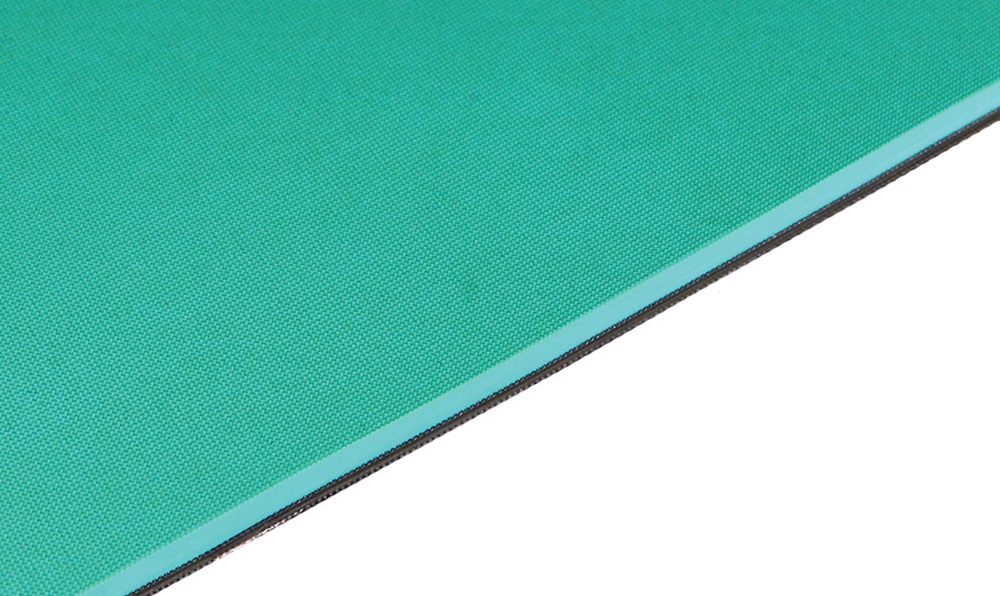

Paper, printing and cardboard

High-speed processes and a sensitive, sometimes heavy product, need the right combination of belt features to ensure high-quality results. Debris from a processing belt, or marking and scratching, can easily ruin or at least reduce product quality. High abrasion resistance prolongs belt lifetime.

High abrasion and wear resistance

Good dimensional stability

Resilience

Consistent coefficient of friction

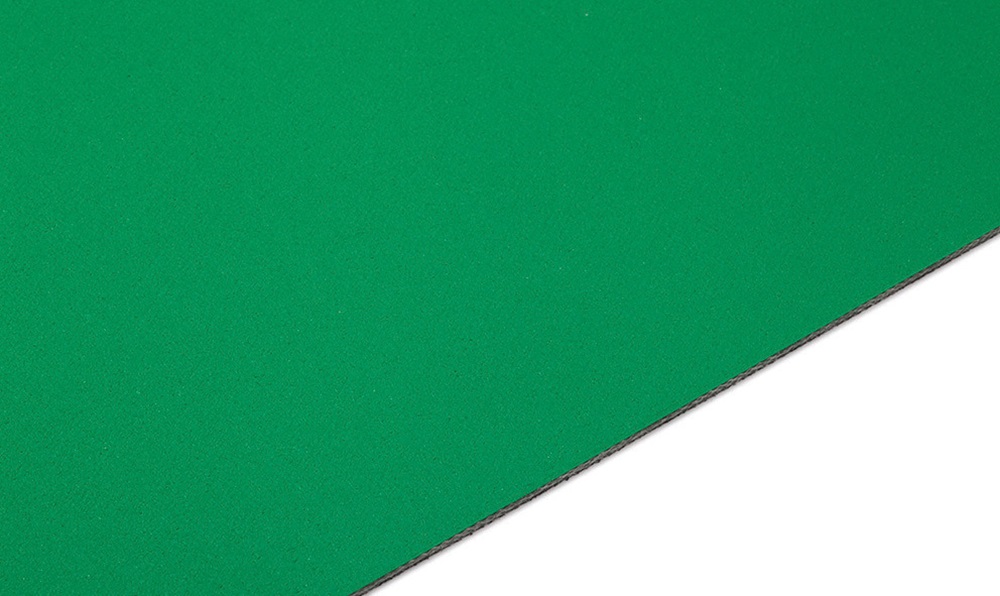

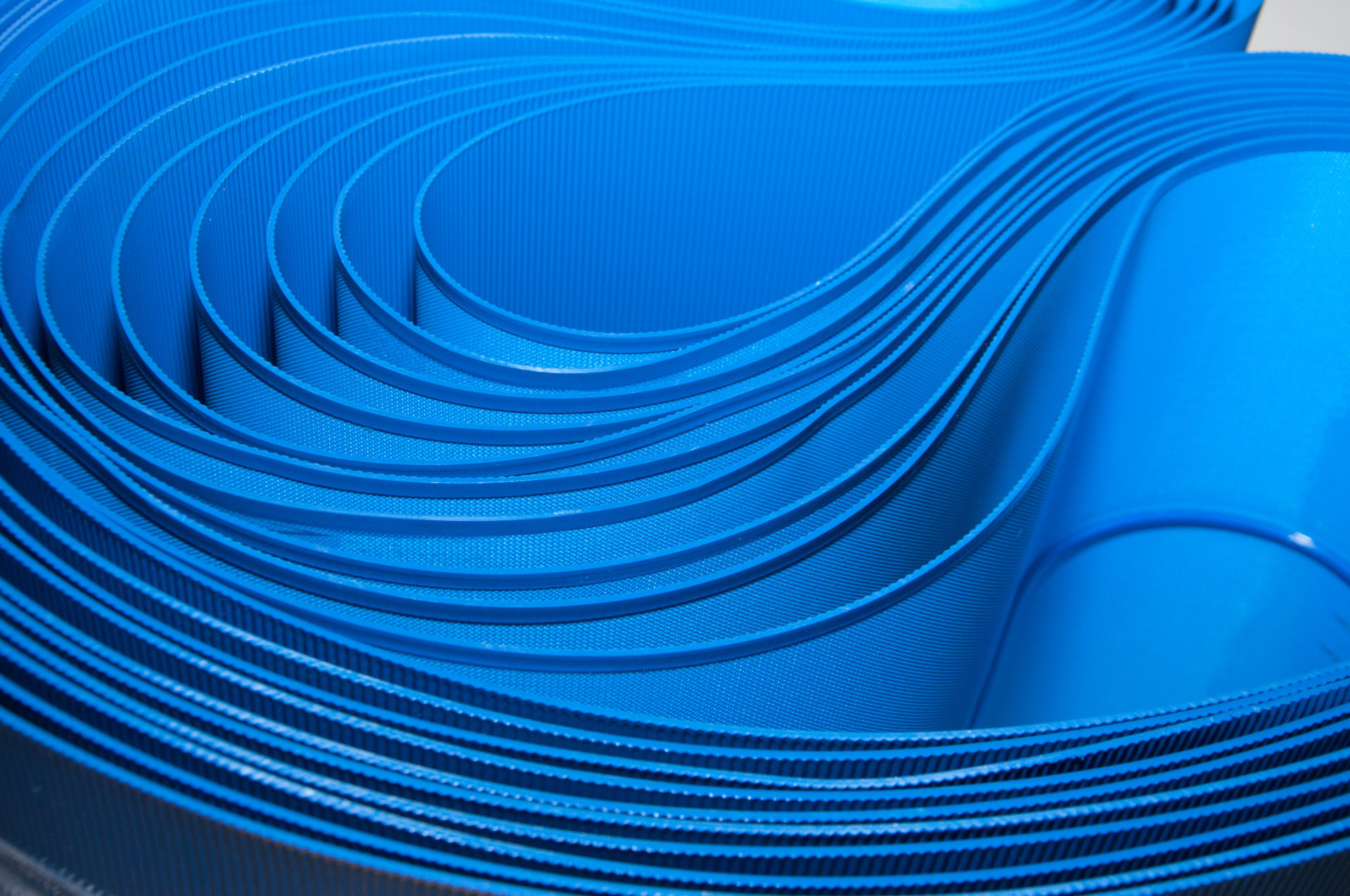

Recycling of aluminum cans, glass, and plastic bottles

Belts in reverse vending machines and other recycling processes often have to withstand liquids or oil residues. The alternating transport of different types of goods, such as glass or plastic bottles as well as cans, means that strong and durable belts are required to ensure steady operation.

Good dimensional stability

High abrasion resistance

Consistent coefficient of friction

Downloads