Changing from polyamide to polyester belts increases life cycle

An end user in the yarn processing industry in Brazil was unsatisfied with their belt. The belt that was used for their draw frame application (breaker & finisher) had a very short life cycle. It frequently had the same “crack in the seam” problem, consequently leading to breakage or rupture after a few hours in use. The customer still insisted on quoting the same belt because it was original. The Habasit representative, however, convinced the customer to consult the machine manual, where they identified the error in the selection of the belt.

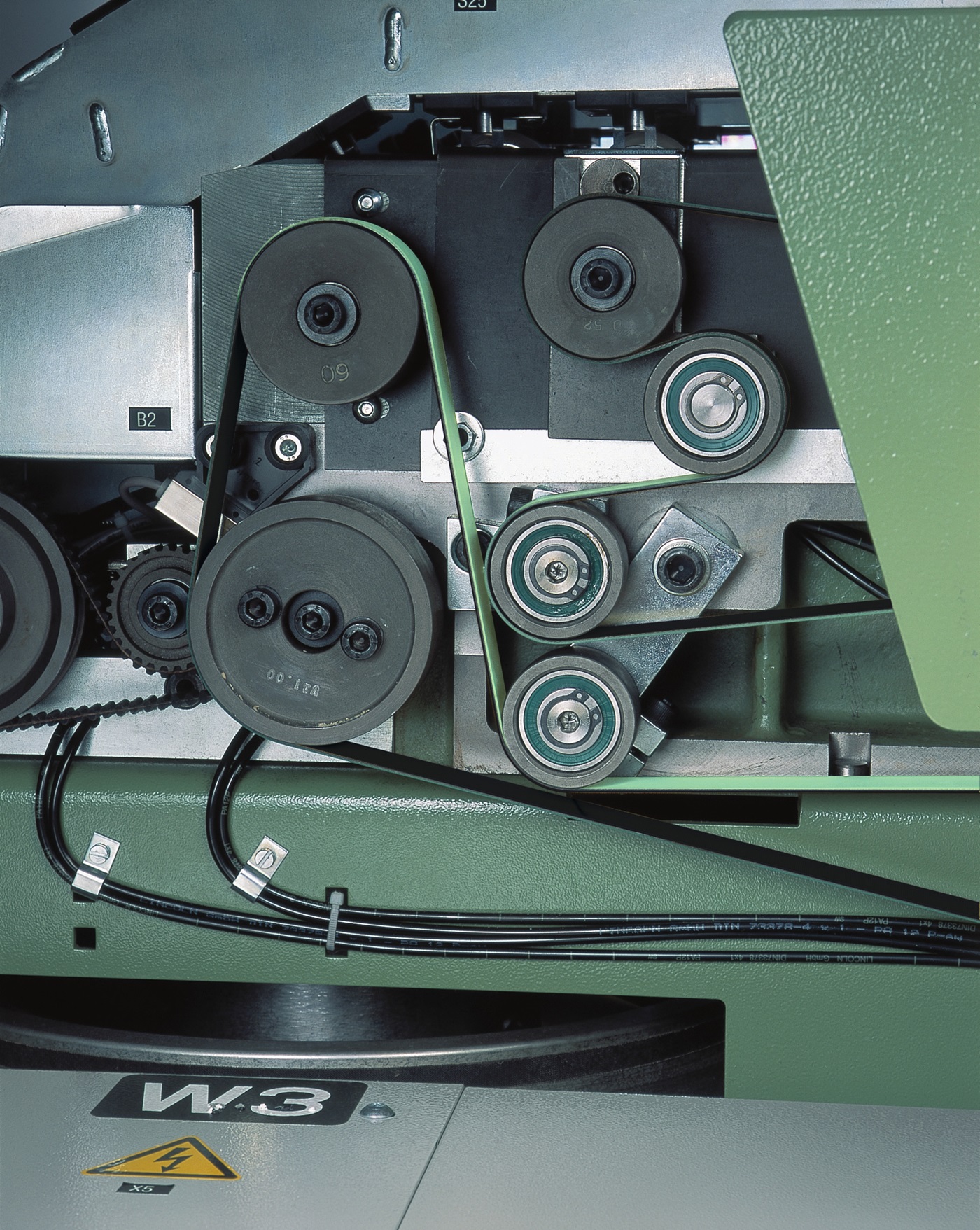

The belt selected in the design had the capacity to withstand a minimum diameter of 40 mm but was unfavorable because it is made of polyamide and needed to be joined with Thermofix, which is not recommended in applications that have counter-flexing. Therefore, the Habasit representative recommended TC-20EF, which allows minimum diameters and can be Flexproof-joined.

The minimum permissible diameter of TC-20EF, along with the perfection in the Flexproof splicing by Habasit is critical to the success of the application. The belts reached 12 months of life cycle and were monitored closely. With 10,500 working hours, they were changed to avoid a correction and it was agreed that they would be changed every 8,760 hours (12 months) in preventive maintenance. Thus, saving a work of 6 hours on each machine alone in this position.

As a result, the customer no longer has any concern with the machine, achieving consistently better efficiency. Habasit gained total credibility in any problem with belts within the company. The customer understood that Habasit is the expert, with excellent support with many resources. As the same problem was presented in other positions, all other polyamide belts were replaced by polyester belts and the result remains satisfactory, also applying to other customers.