Tailored solutions for optimal performance

The Habasit seamless belt portfolio consists of woven endless and knitted endless belts, as well as synchronous and non-synchronous endless substrates. The belts can be coated with no splice or seam, providing uniform physical properties during the entire belt service life.

Our manufacturing processes and ideal combination of materials ensure optimal design for your specific application requirements. Habasit seamless belts offer reduced lifecycle costs, as well as smooth and vibration-free operation, especially at high speeds.

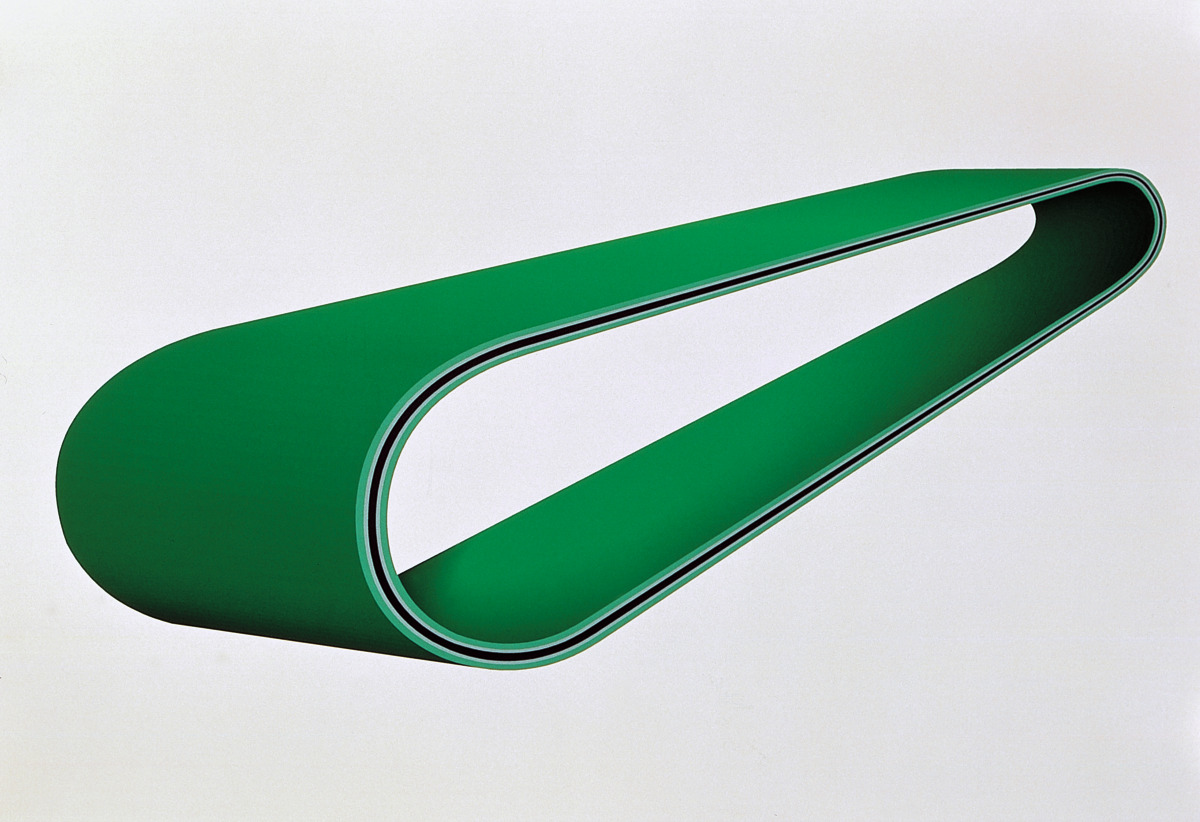

Belt Design

The seamless belt substrate (fabric) is manufactured endless on looms, or knitted as a tube. The threads are wound in a spiral in the belt running direction. The belt circumference is determined by the diameter of the spirals, while the required width is obtained by slitting the tube. To achieve the necessary properties and dimensional stability, the belt substrate is coated with a specific elastomer and treated in a special thermal process. Seamless belts are available in stable, semi-stable, semi-elastic, and elastic versions.

Habasit GRABBER seamless belts

GRABBER seamless belts are mainly used in folder gluer (FG) or feeding applications where non-synchronous motion is required.

GRABBER timing belts are primarily used in Vertical Form Fill Seal (VFFS) and other pulling applications where synchronous motion is required.

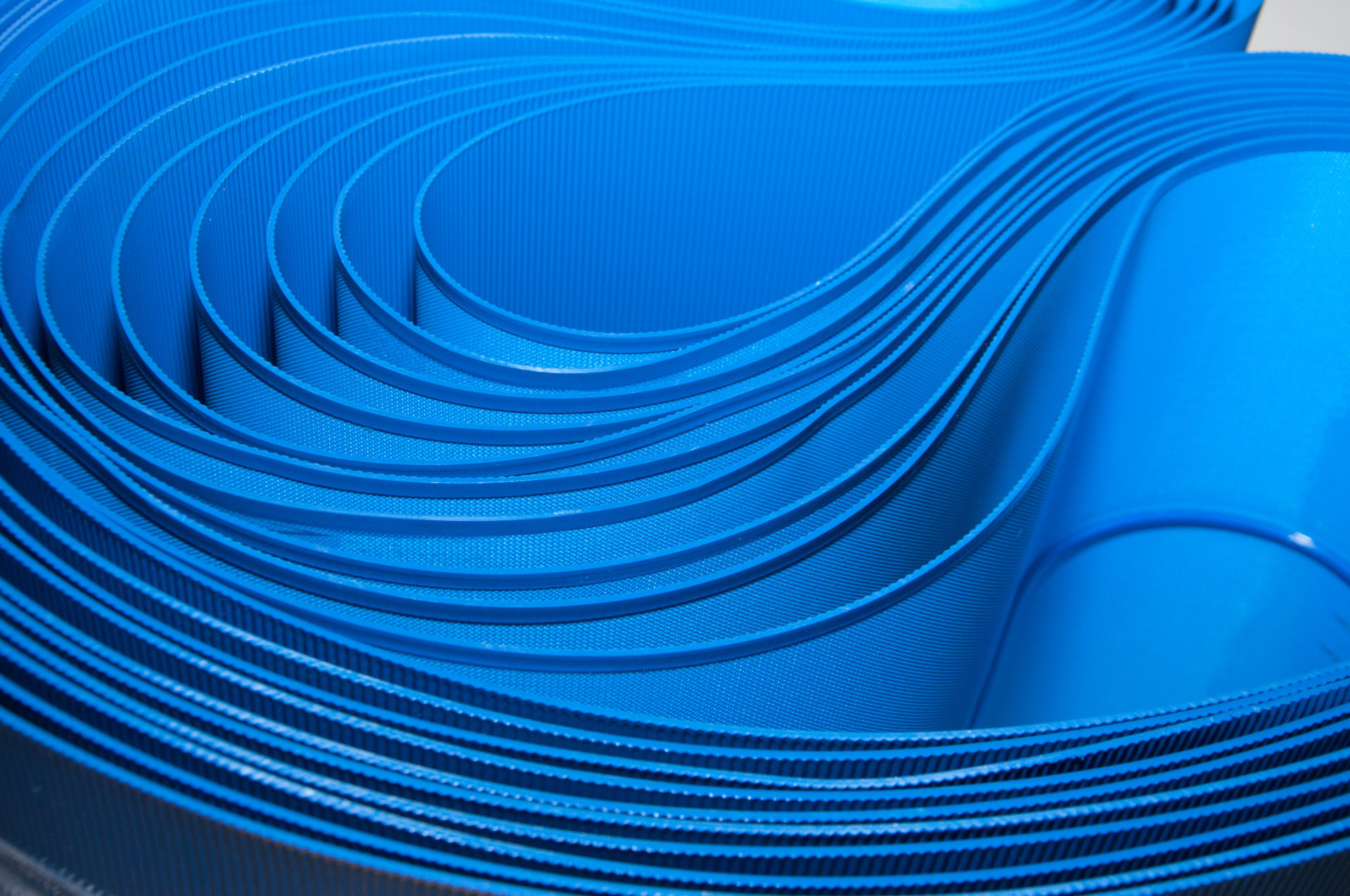

Traditional seamless belts

These belts are produced by weaving or knitting a “tube” of fabric material in a circular fashion. The belts are then coated with various rubber or plastic materials depending on the application requirements. Since the belts do not have a splice, they are very strong for the given thickness and can also be produced to hold very tight length tolerances.

Power Transmission Belts

Habasit seamless power transmission belts are used to transmit power in light duty applications, including lathes, grinders, vacuum cleaners, and spindle drives. A variety of strengths are available based on different fabric designs.

Conveying Belts

Habasit seamless conveying belts are used for transporting light objects, usually at higher speeds, such as: paper, currency, tickets, and envelopes. Various strengths are available based on different fabric designs. Different friction values are achieved through the selection of the top cover compound.

Endless woven belts

Browse the wide selection of Habasit belts, accessories and conveyor components

Downloads