Modular solutions for bakery and confectionery

HabasiLINK plastic modular belts for food industry applications are made with food-safe materials and comply with relevant food industry regulations.

They are engineered with a number of features for more efficient operations, such as dynamic open hinge design for ease of cleaning or the micropitch range for tight transfers.

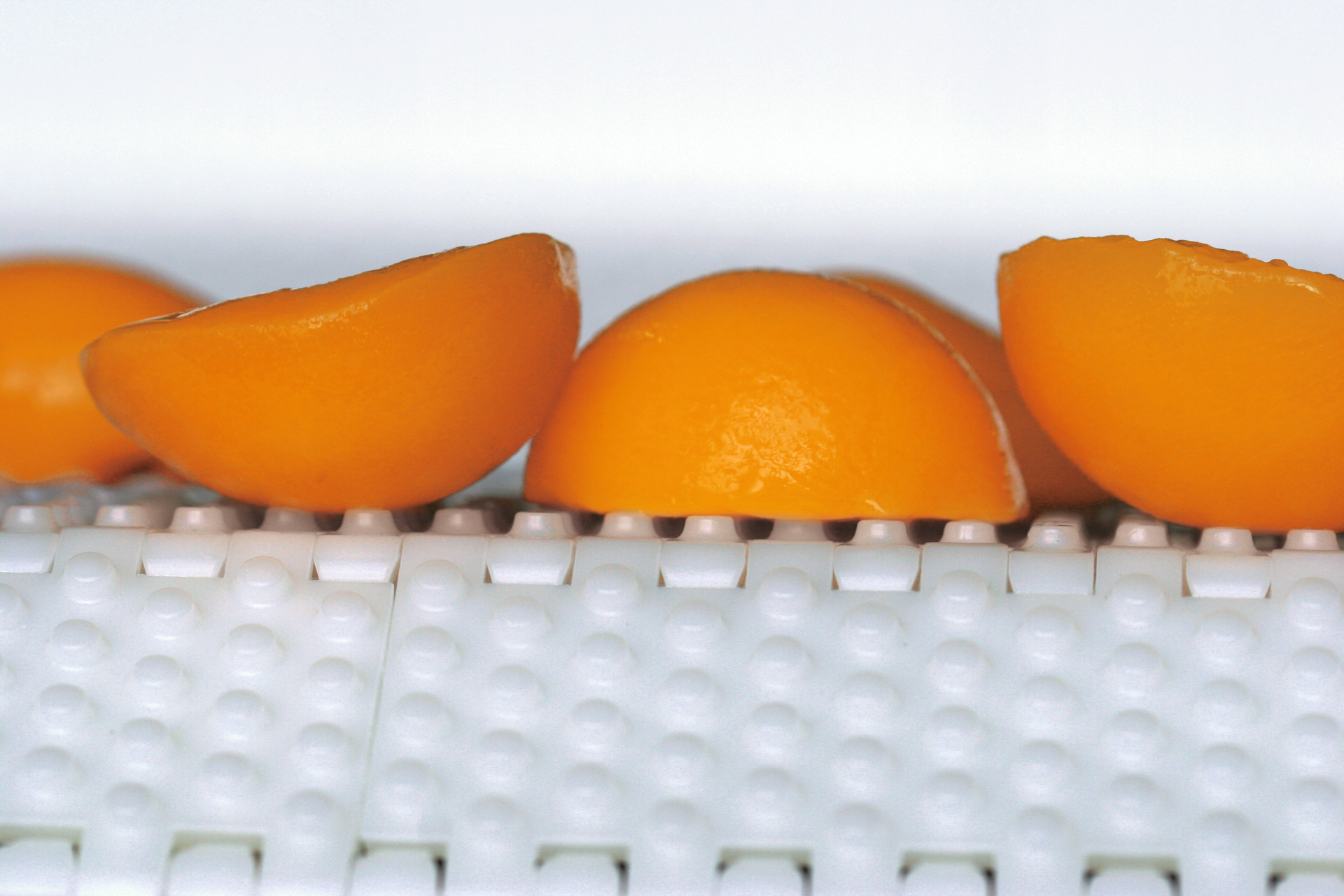

Managing tight transfers

Habasit can provide a full range of plastic modular belts that can face a transfer diameter of up to 6 mm, in combination with multiple surfaces such as Flat Top, Flush Grid, Diamond Top, Cone Top, and Non Slip.

The Micropitch series (0.3” pitch) delivers reliable belt tracking on small knife edge transfers, combined with a superior sprocket engagement and maximum application flexibility.

HabasitLINK for spiral conveyors

Spiral conveyors are used in the bakery industry for some of the most important processes such as proofing, cooling and freezing.

The HabasitLINK spiral belts deliver a high airflow and their rounded surfaces prevent product marking. The range of solutions includes belts with multiple collapse factors to optimize the machine footprint and a wide material portfolio to handle your required temperature range.

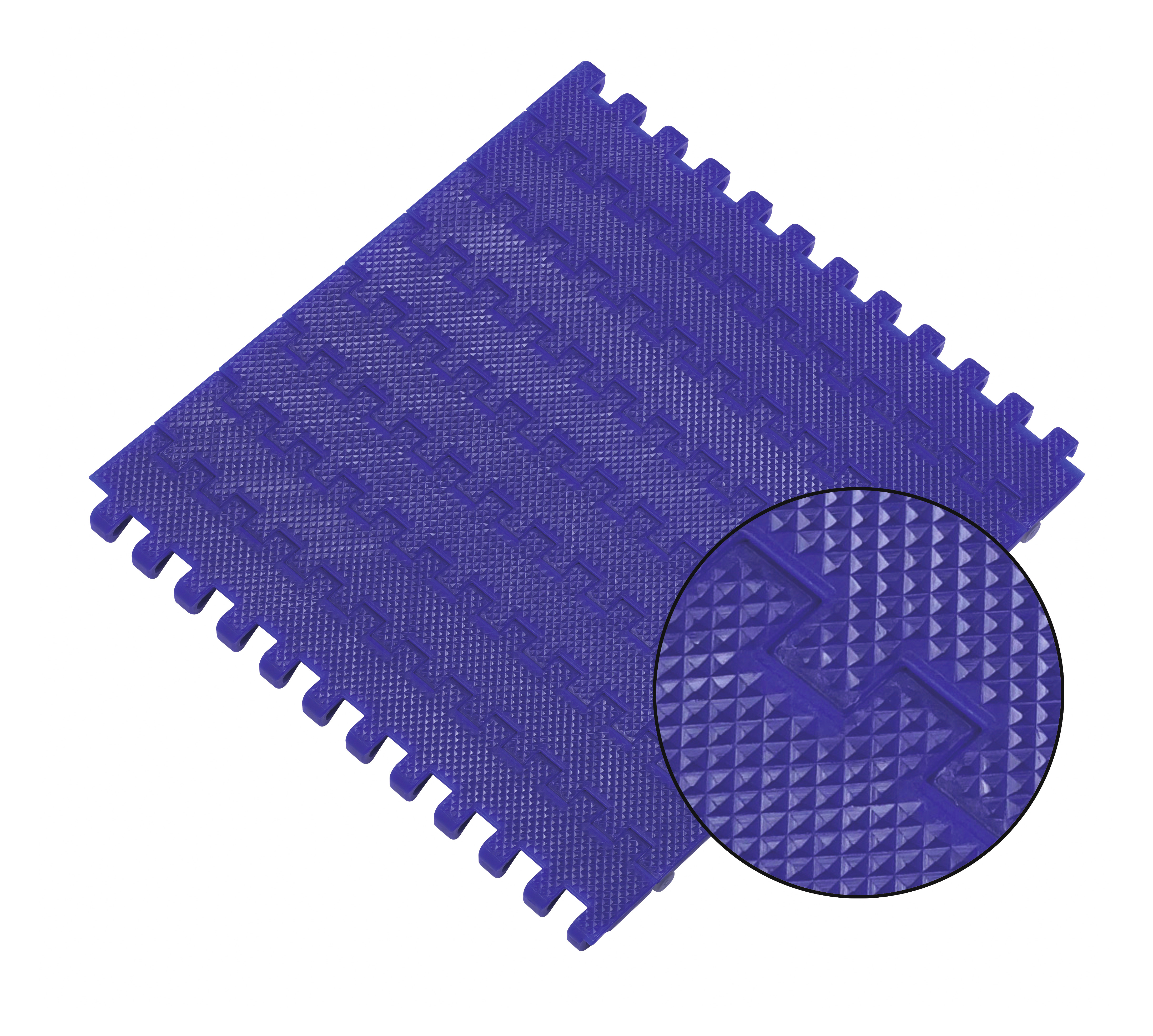

Diamond top belts

While not yet baked, the dough is a challenging item to be handled through the initial phases of the bakery process. In fact, it is naturally sticky and the vacuum effect on flat surfaces prevents its transfer from the belt to the next one.

To improve the release of dough, flour is often used to prevent excessive sticking.

The diamond top pattern (embedded pyramid) of the belt ensures excellent adherence of flour and a good release of raw dough, extending its effect a long time.

Metal and X-ray detectable materials

Habasit understands that product contamination proceeding from foreign bodies in the production flow can seriously affect food safety and the producer's reputation.

External objects, unexpected mechanical accidents, and strong impacts along the line might bring in or break off small pieces or parts that are not easy to be detected within the production flow. Habasit supports the food processors to produce safe food and protect their brand.

With the scope to improve the overall food safety, along the years we developed a broad range of food approved metal and X-ray detectable raw materials. Belt elements can easily be detected by the inspection machines exactly the same as any other material or high-density contaminants, such as metal, bones, and glass.

Featured products