La limpieza del mañana, hoy

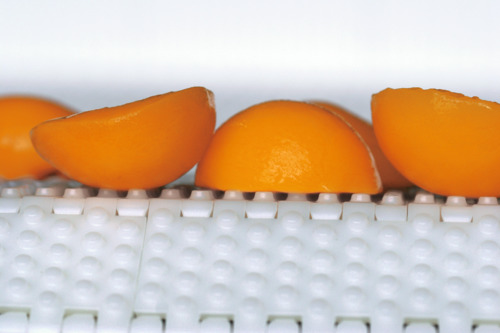

Uno de los mayores retos de la industria alimentaria actual, es el mantenimiento de unas condiciones higienicas óptimas. Por ello, un diseño higiénico y fácil de limpiar son requisitos importantes para los equipos utilizados in los procesos alimentarios.

Los transportadores de banda tienen una importancia clave ya que a menudo se encuentran en contacto con los alimentos.

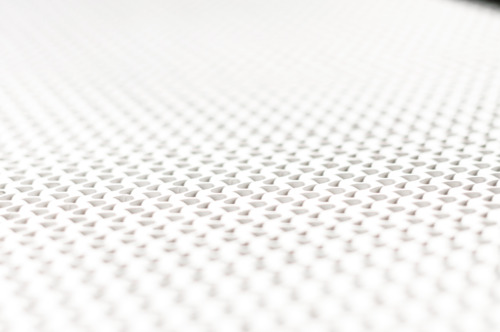

Las bandas modulares Habasit HyClean han sido desarrolladas para mejorar las condiciones de higiene y los procesos de limpieza.

Las bandas modulares Habasit HyClean han sido desarrolladas para mejorar las condiciones de higiene y los procesos de limpieza.

Optimizado para la limpieza

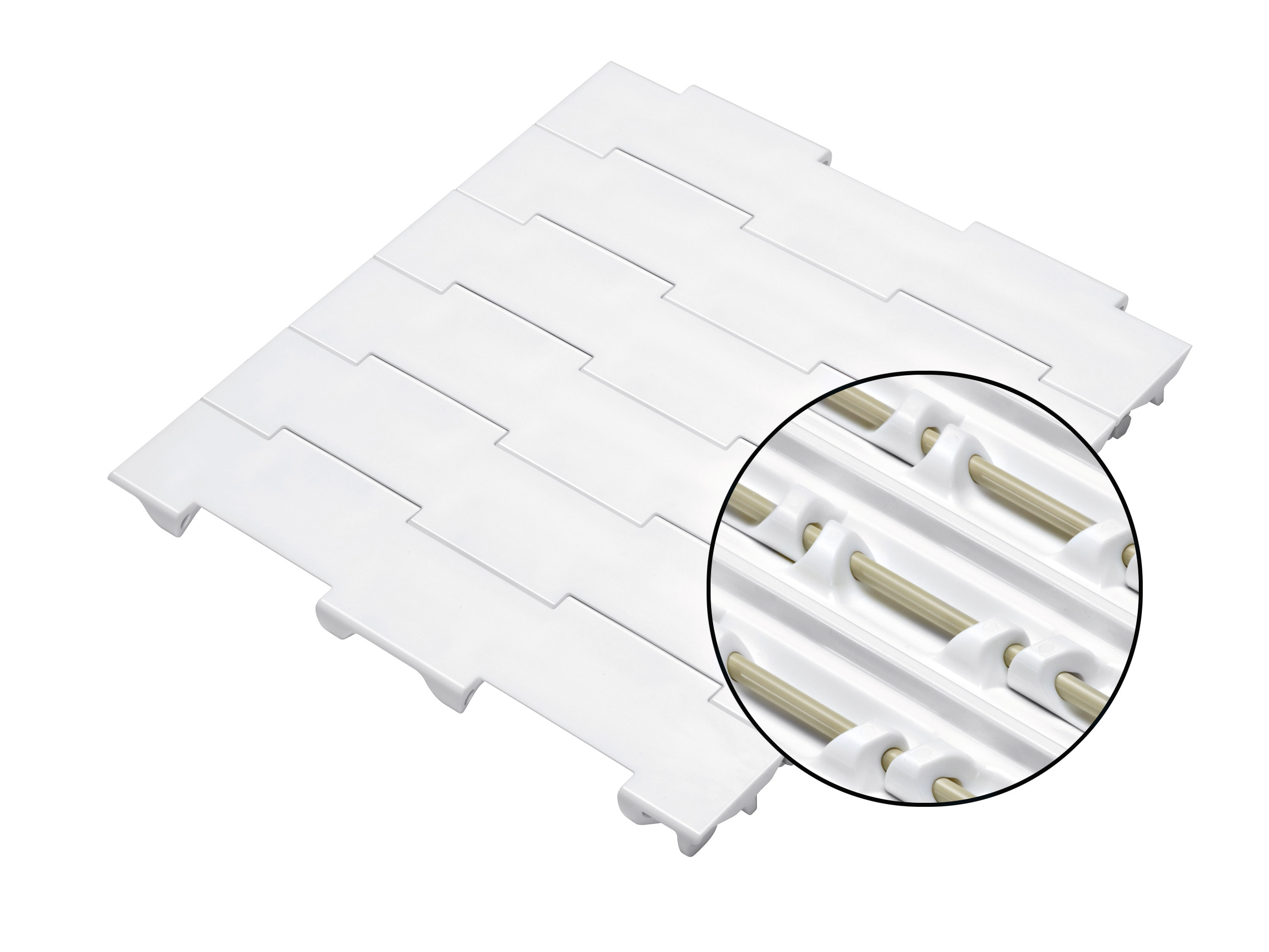

Las bandas Habasit HyCLEAN se caracterizan por su mayor exposición de las varillas, una reducción significativa de las bisagras, y el uso de módulos anchos, lo cual reduce la cantidad de huecos en la banda.

El resultado es una exposición de las varillas del 85%, para facilitar la limpieza.

La serie HyCLEAN incluye una banda flat top de 2" y un piñón con un diseño patentado único.

Las bisagras de tipo dinámico, con links extra anchos y agujeros para varilla ovalados, evita la acumulación de residuos, facilitando la limpieza. Los piñones tienen un espacio entre dientes, lo cual minimiza la superficie de contacto con la banda, sin comprometer el engranaje.

Las bandas Habasit HyCLEAN ofrecen un diseño único en el mercado, con una exposición de la bisagra del 100%.