Innovation without precedent.

Precision without compromise.

In digital printing, accuracy and performance are key to delivering results. Traditional belt systems – held back by mechanical tolerances – limit these goals.

That’s why Habasit created the Smart Printing Belt, a patented, end-to-end solution that redefines belt position measurement.

While leading printers manage ±50–150 µm belt position accuracy, the Smart Printing Belt achieves repeatable ±10 µm precision, thanks to a radical new measurement methodology.

Developed entirely in-house, this unique solution is real-time, reliable, and more accurate than anything else on the market. Ideal for complex designs on textiles, detailed ceramics, and wood, it ensures print stability, clean registration, and top-quality results – without the need for machine redesign.

10 Microns - How is That Even Possible?

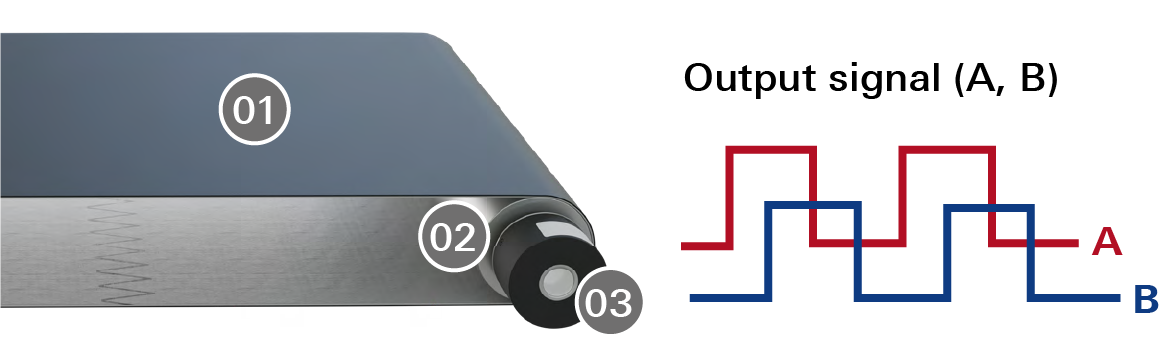

Indirect belt position measurement

(the standard methodology)

- Printing belt

- Driver roller

- Rotary encoder

Indirect measurement with a rotary encoder often leads to inaccuracies caused by:

- Mechanical tolerances (gearbox play, motor play, roller runout)

- Belt-related challenges (tension, belt joint effect)

When print positions shift and registration becomes unreliable, every error impacts performance - especially on long print paths with multiple print bars and stations.

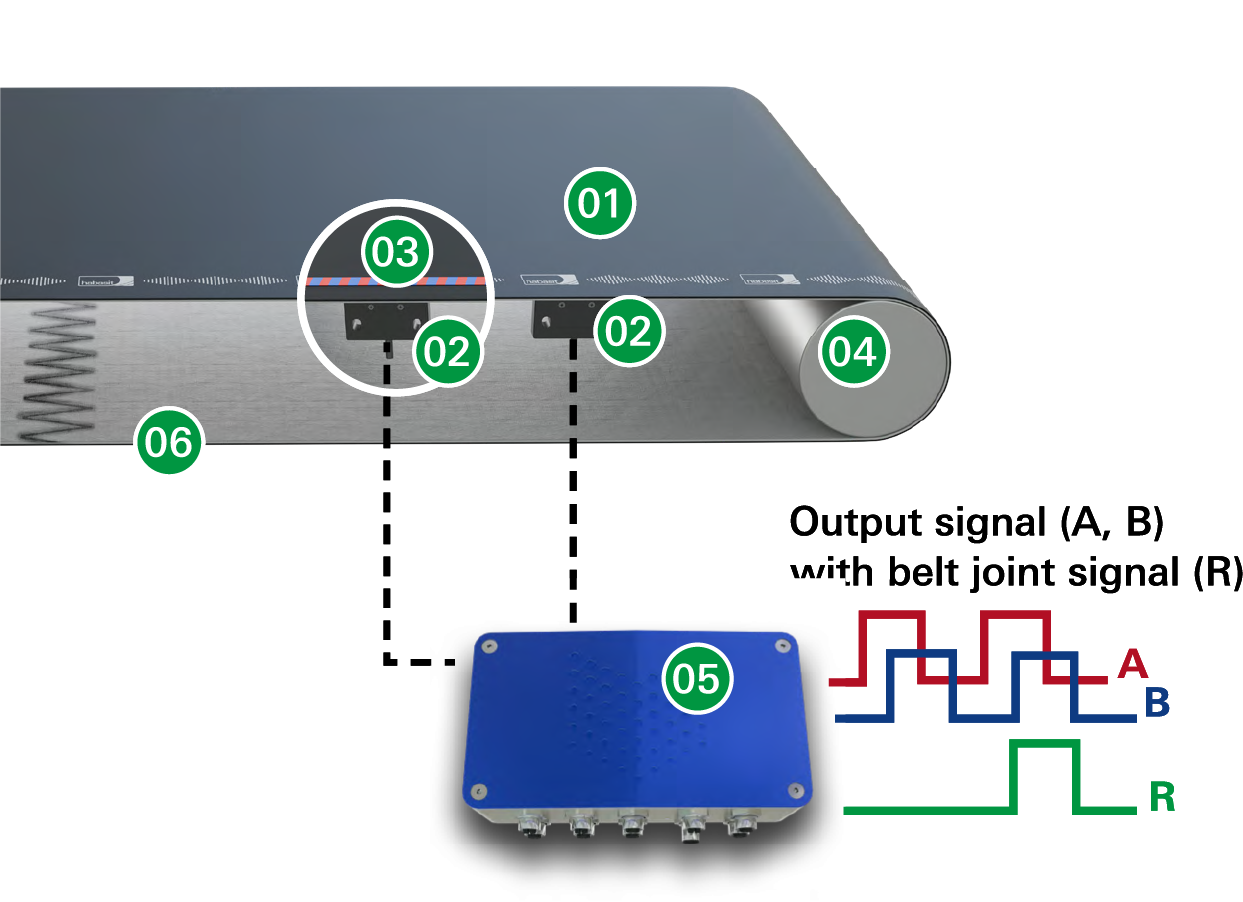

Direct belt position measurement

(with the Smart Printing Belt by Habasit)

- Smart Printing Belt

- Sensore head

- Embedded magnetic layer

- Driver roller

- Central processing unit

- Belt joint

Habasit Smart Printing Belt working principles

- Magnetic layer embedded inside the belt

- Four sensors mounted under or above the belt

- A processor calculates position in real time

- Digital twin model continuously updates via machine learning

- Standard output signals compatible with existing systems

How it works

By measuring position directly from the belt itself – thanks to a magnetically embedded layer and sensors feeding real-time data into a central processor – this system leverages a digital twin for instant modeling and correction.

The result? Industry-leading ±10 µm accuracy – with no moving sensor parts, no encoder drift, and no operator calibration required.Enjoy predictive intelligence and stability with perfect droplet placement, reduced setup times, and higher productivity – even in your most complex applications.

The advantages

- Eliminated inaccuracies caused by moving components

- Central processor with a self-learning digital twin that dynamically adjusts in real time

Key Benefits at a Glance

Repeat Accuracy

- No more seams and printhead overlaps

- Sharper, crisper details with sub-pixel precision – no banding or blurring

- Consistency in returning to the same position indefinitely

- Repeat accuracy over long runs exceeding 500 meters

Consistent Precision

- No manual recalibration required

- Automatic, continuous calibration

- Belt position adjusts to changing conditions without disrupting production

Reliability and Durability

- Direct belt position measurement, independent of moving parts

- Built on best-in-class Habasit Printing Belt technology

Easy Integration

- Integrates with new machines or retrofit systems – no redesign needed

- Sensors mount above or below the belt

- Belt can be joined directly on the machine, just like a standard belt

Cost Savings

- Reduced waste and rework

- Fewer errors = less scrap and ink waste

- Repeat accuracy ensures long-term process efficiency

Designed for High Performance Across Industries

Step into the next generation of digital printing with Habasit’s patent-protected Smart Printing Belt – created for industries where precision is essential.

Perfect for:

- Textile printing

- Ceramic tile decoration

- Cardboard & packaging graphics

- Wood-based & engineered panels

- Other high-resolution applications

With chemical resistance, thermal stability, and real-time calibration, the Smart Printing Belt is ready for the most demanding environments – and the most ambitious designs.

Ready for Smarter Printing?

Reimagine what's possible in digital printing.

Downloads