Enhancing hygiene in meat, poultry, and fish

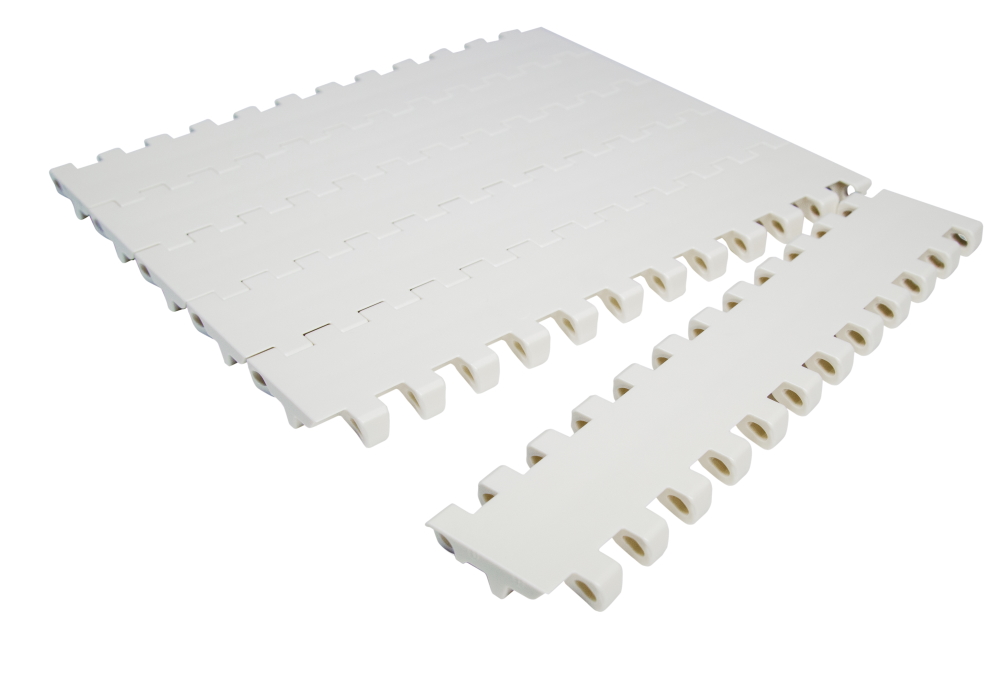

HabasiLINK plastic modular belts for food industry applications are made with food-safe materials and comply with relevant food industry regulations.

They are engineered with a number of features for more efficient cleaning, such as dynamic open hinge design.

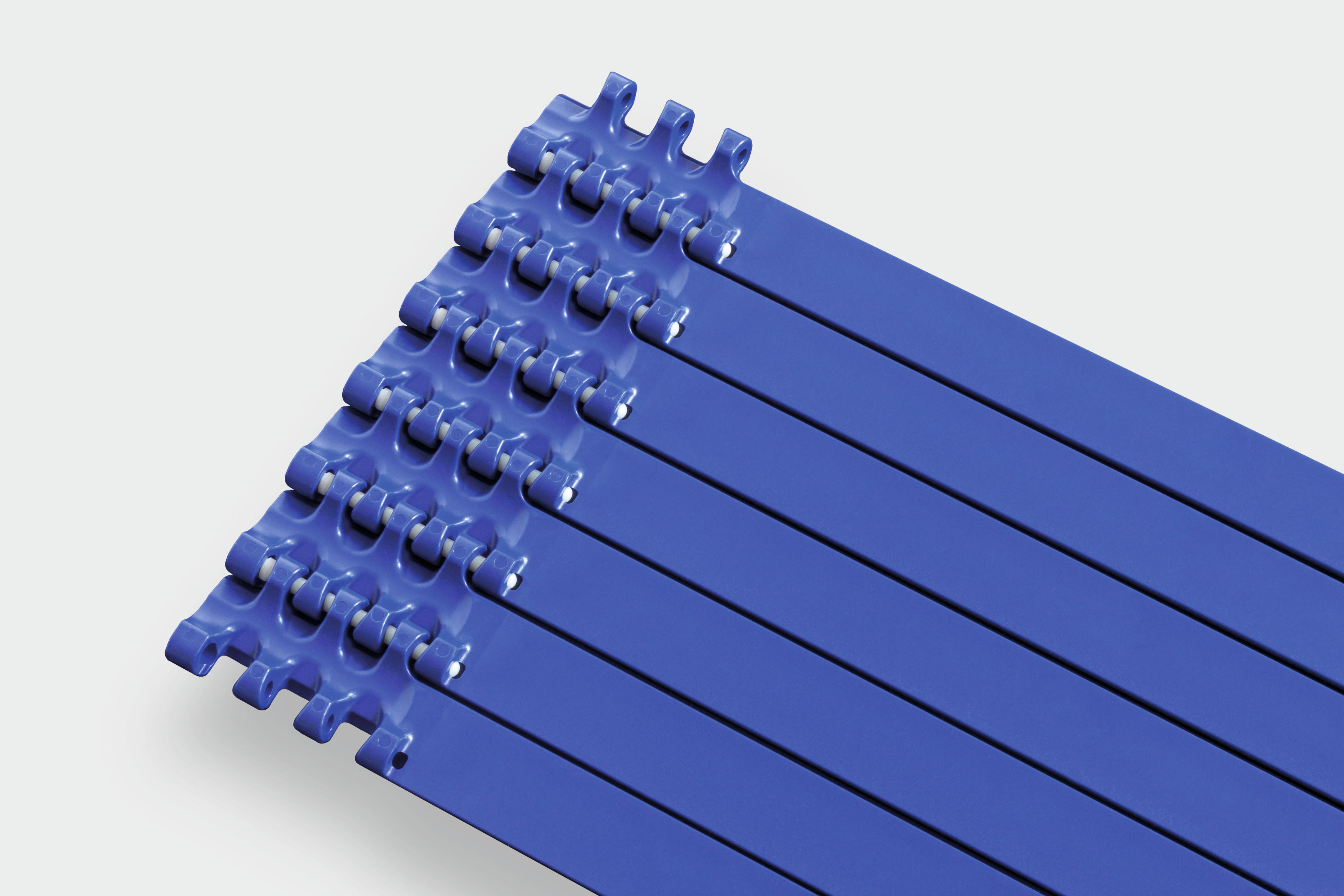

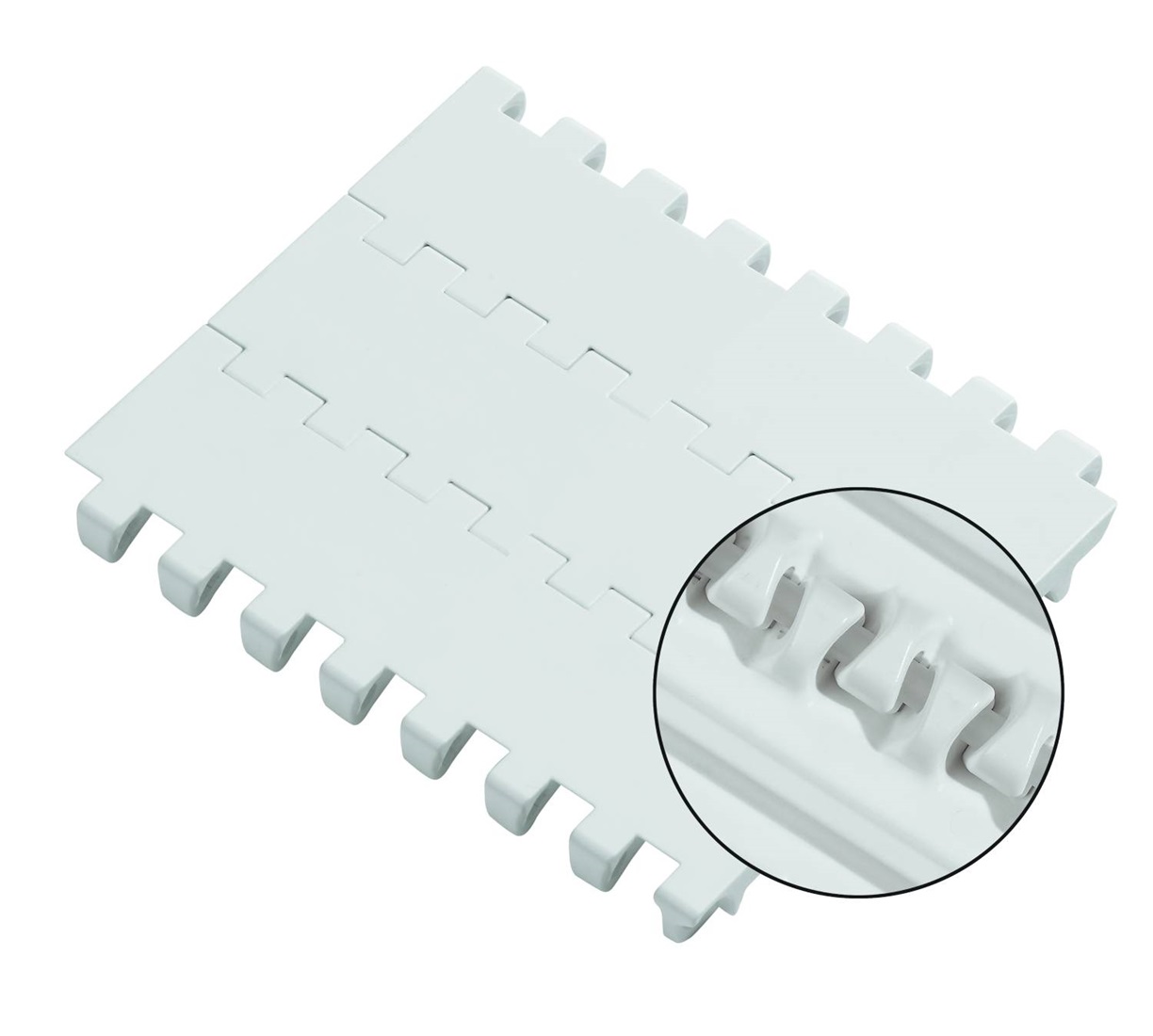

Unique hinge design

To resolve this problem, Habasit introduced the dynamic open hinge design which delivers a higher rod exposure.

When the running belt rows face the sprockets, their axial rotation exposes different parts of the belt rod to the cleaning agents and therefore facilitates the easy removal of all potentially accumulated organic debris. As a result, the entire surface of the rod is cleaned.

When the sanitation requirements are even more demanding, the rod exposure is taken to the next level: the HabasitLINK HyCLEAN belts.

Cone top and nonslip belts

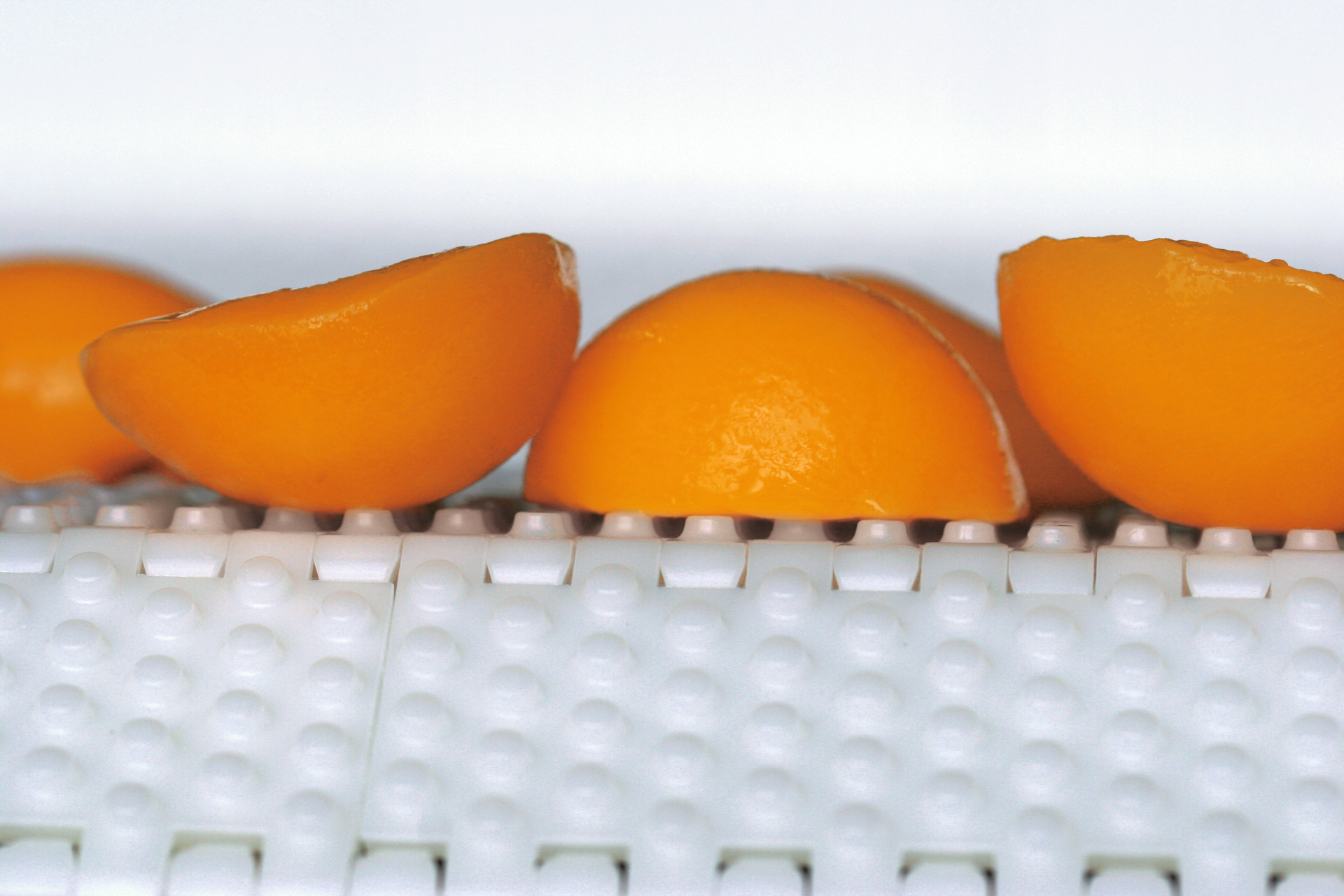

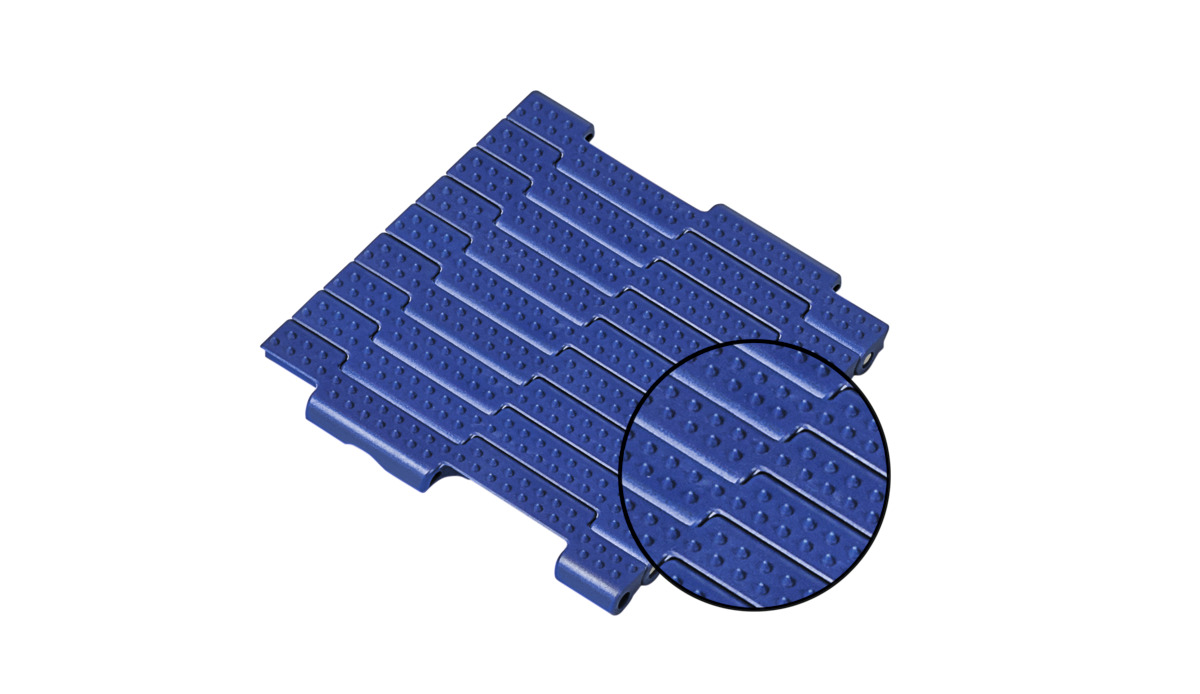

In some cases in the wet, fatty, and slippery environment of protein applications, a firm but gentle product retention is required along with a tight product transfer.

The HabasitLINK Mictropitch ConeTop (M0863) and Non-Slip (M0873) belts have been designed for wet food and protein applications, within the red meat, poultry, and fish industries.

These belts avoid any undesired product displacement and keep the meat in the right position without damaging the product surface in contact with the belt. The specifically engineered sharp cone top surface is the right compromise between a firm grip and gentle product handling.

M0800 belt series design is suitable to run on a 6 mm diameter knife edge which is the smallest on the market for plastic modular belts. This feature allows a very safe and tight product transfer and minimizes product positioning issues.

Metal and X-ray detectable materials

Habasit understands that product contamination proceeding from foreign bodies in the production flow can seriously affect food safety and the producer's reputation.

External objects, unexpected mechanical accidents, and strong impacts along the line might bring in or break off small pieces or parts that are not easy to be detected within the production flow. Habasit supports the food processors to produce safe food and protect their brand.

With the scope to improve the overall food safety, along the years we developed a broad range of food approved metal and X-ray detectable raw materials. Belt elements can easily be detected by the inspection machines exactly the same as any other material or high-density contaminants, such as metal, bones, and glass.

WHI - The ultimate solution for demanding applications

HabasitLINK plastic modular belts have expanded to offer better wear-, hydrolysis- and impact resistance. The new HabasitLINK WHI material has been developed to offer a solution when high quality POM suffers from shortened service life due to its limitations.

WHI has been specially engineered for red meat, fish, and poultry applications where high strength and chemical and impact resistance are a necessity.

Habasit’s WHI material for HabasitLINK offers enhanced resistance to mechanical stress and demanding cleaning conditions and brings important benefits to you. The combination of extended belt lifetime, increased production yield, as well as better food safety and cleaning will contribute to the success of your production line and overall business.

Featured products

Downloads