Flexseal Sealed Edges Enhance Hygiene, Food Safety and Service Life

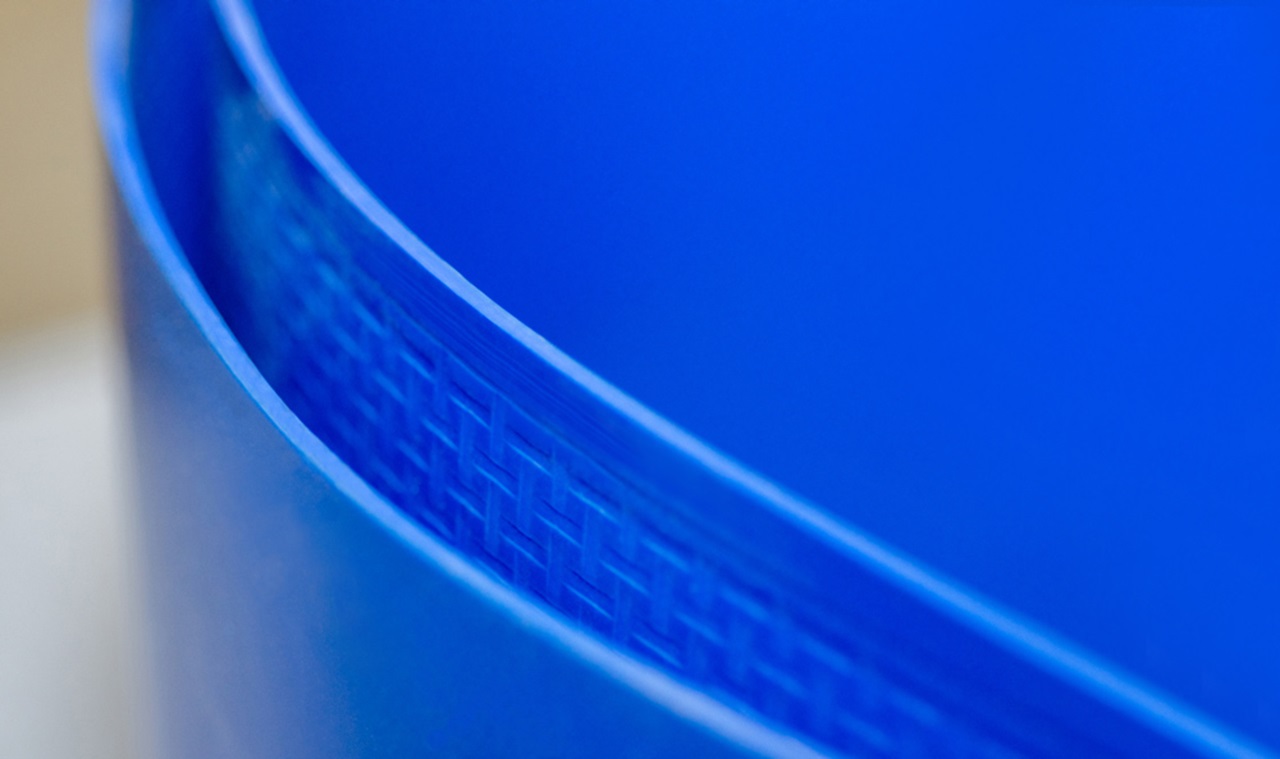

In the Flexseal manufacturing process, both edges of the belt are encapsulated in thermoplastic to seal fabric layers. The encapsulated edges create a more durable, hygienic construction that prevents fraying, wicking, and minimizes the potential for layer separation; serving to inhibit food contamination and enhance sanitation. Flexseal has proven to dramatically reduce the impacts of edge abrasion on Habasit, food-grade TPU belts.

Flexseal edges are ideally suited for bakery, confectionery, meat, poultry, dairy, fruit, vegetable, tobacco, and other agricultural processing applications, plus non-food applications that cannot tolerate the risk of belt-edge fraying.

Advantages

Enhanced food safety

- FDA compliant on applicable belt types

- USDA certified enhancement for select belts

- Easy, more complete cleaning & sanitation

- Eliminates fabric fiber contamination

Increased service life

- Robust and durable, mitigating edge damage

Small transfers

- Excellent flexibility for use on nosebars

Flexseal proved to decrease the edge abrasion of a Habasit, food-grade TPU belt, by 33%, in laboratory testing.

For more information on Flexseal and the laboratory results download our flyer and talk to your Habasit specialist. Habasit America's service network is ready to serve you wherever you are located.