Fabric Belt Joining Methods: An Overview

Fabric belts have been a core part of Habasit’s portfolio since our founding in 1946. Through continuous improvement, we refined our manufacturing processes and created stronger, more resilient belts.

Equally important is our approach to joining these belts. The joint is often the weakest point in a fabric belt. Because of this, we’ve refined the four most effective joining methods:

- Flexproof

- Quickmelt

- Thermofix

- Mechanical lacing

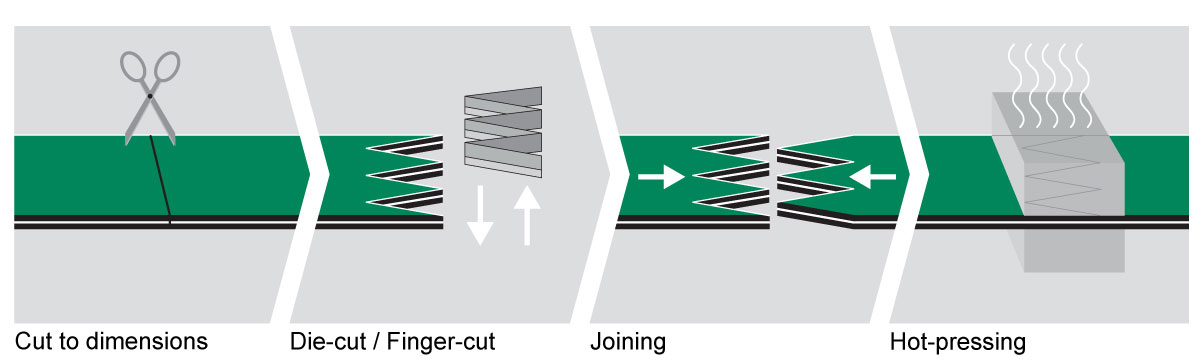

Flexproof Joining

Flexproof joining creates a fusion joint by heating the belt’s thermoplastic material until it melts, then pressing the belt together along the weld line. The weld line is extended by using a finger pattern, thereby enhancing the joint’s strength without the need for adhesives.

Advantages:

- High flexibility, enabling smaller pulley diameters.

- Increased weld line results in higher tensile strength.

- Ideal for belts containing thermoplastic layers.

- Adhesive-free method, simplifying the joining process.

Considerations:

- Not suitable for high temperatures; maximum operating limit: 60–80 °C (140–176 °F).

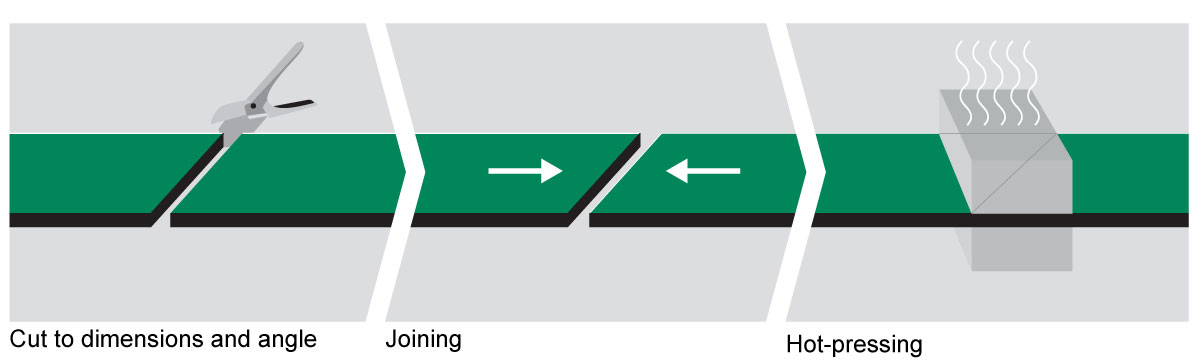

Quickmelt Joining

Quickmelt is another fusion joint method noted for its simplicity and speed. The belt ends are cut at an angle, and the butt ends are placed together in a guide rail and then heat-pressed. This creates a secure, adhesive-free bond.

Advantages:

- Fast and straightforward method, ideal for on-site belt installation.

- Provides flexibility at the joint, supporting use with smaller pulleys.

- Adhesive-free method, simplifying the joining process.

Considerations:

- Limited to lower operating temperatures (60–80 °C / 140–176 °F).

- Not as strong as the Flexproof method.

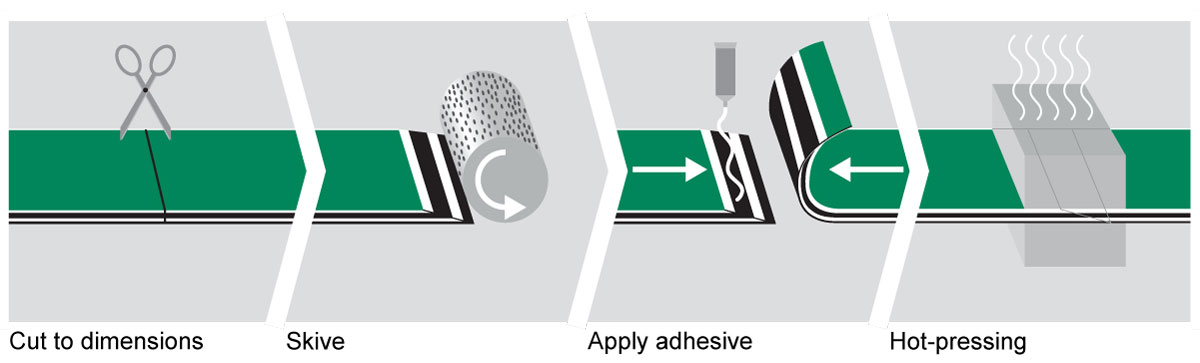

Thermofix Joining

The thermofix method is used to join thermoset plastics. Belt ends are skived into complementary wedge shapes and bonded securely using adhesive, heat, and pressure.

Advantages:

- Suitable for non-thermoplastic materials, such as rubber or silicone, when combined with polyamide tapes.

- Excellent for high-resilience or shock-resistant applications.

- Operates effectively at higher temperatures (up to 100°C / 212°F).

Considerations:

- Increased stiffness at the joint, thus not recommended for small pulley diameters.

Mechanical Lacing

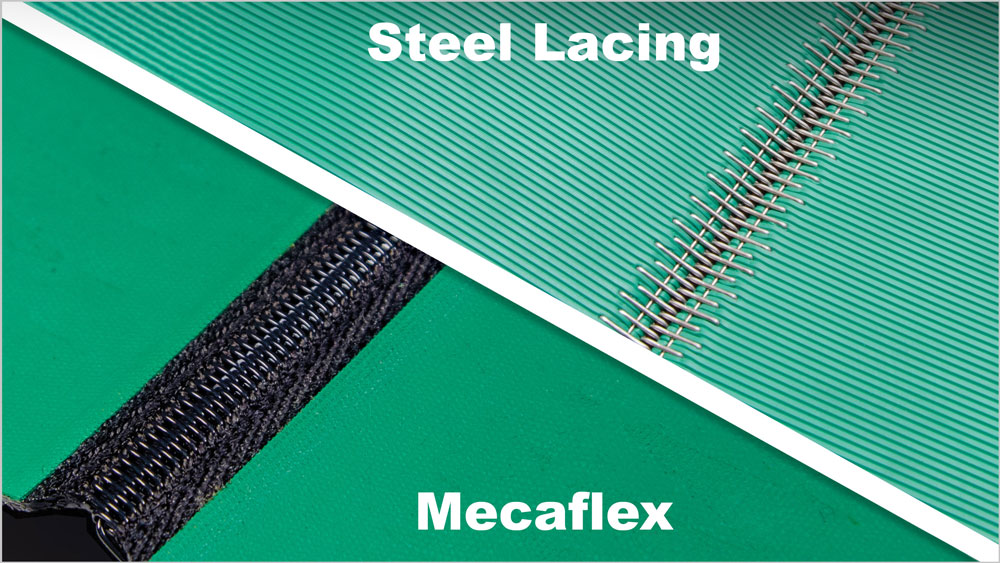

Mechanical lacing uses metal or plastic fasteners attached to the belt ends via a pneumatic press or roller. A metal or plastic pin secures the joint. The three common styles of lacing are steel lacing, Mecafast, and Mecaflex.

- Steel lacing is directly pressed onto the belt ends.

- Mecafast plastic lace is attached to a short fabric segment and then bonded to the actual belt using the Thermofix method.

- Mecaflex plastic lace similarly uses a short fabric segment but is bonded via the Flexproof method.

There are several preparation options available for mechanical lacing. These include a hidden or recessed lace, where the lace is installed below the belt surface. Another option is a "flap-over hidden lace," featuring a flap of belt material covering the lace, providing additional protection and a smoother belt surface.

Advantages:

- Excellent for quick or frequent belt changes.

- Field installation requires no special tools once the lace is attached.

Considerations:

- Initial attachment requires specialized equipment. Habasit provides pre-installed lace options for convenience.

Making the Right Choice

Each joining method offers specific advantages depending on factors such as operating temperature, flexibility, ease of installation, and maintenance requirements. For optimal results, consult your belt’s specific joining datasheet, available on Habasit’s Product Portal.