Load Capability of Habasitlink® M0870 Delivers Higher Performance & Longer Service Life

A beverage manufacturer and distributor was transferring packaged cans and bottles to a storage area and using a modular belt to provide a small transfer point. After about 30-45 days of use, the belt stopped moving under the load of cans and bottles. This caused the sprockets to disengage and bend after rotating against the stationary belt.

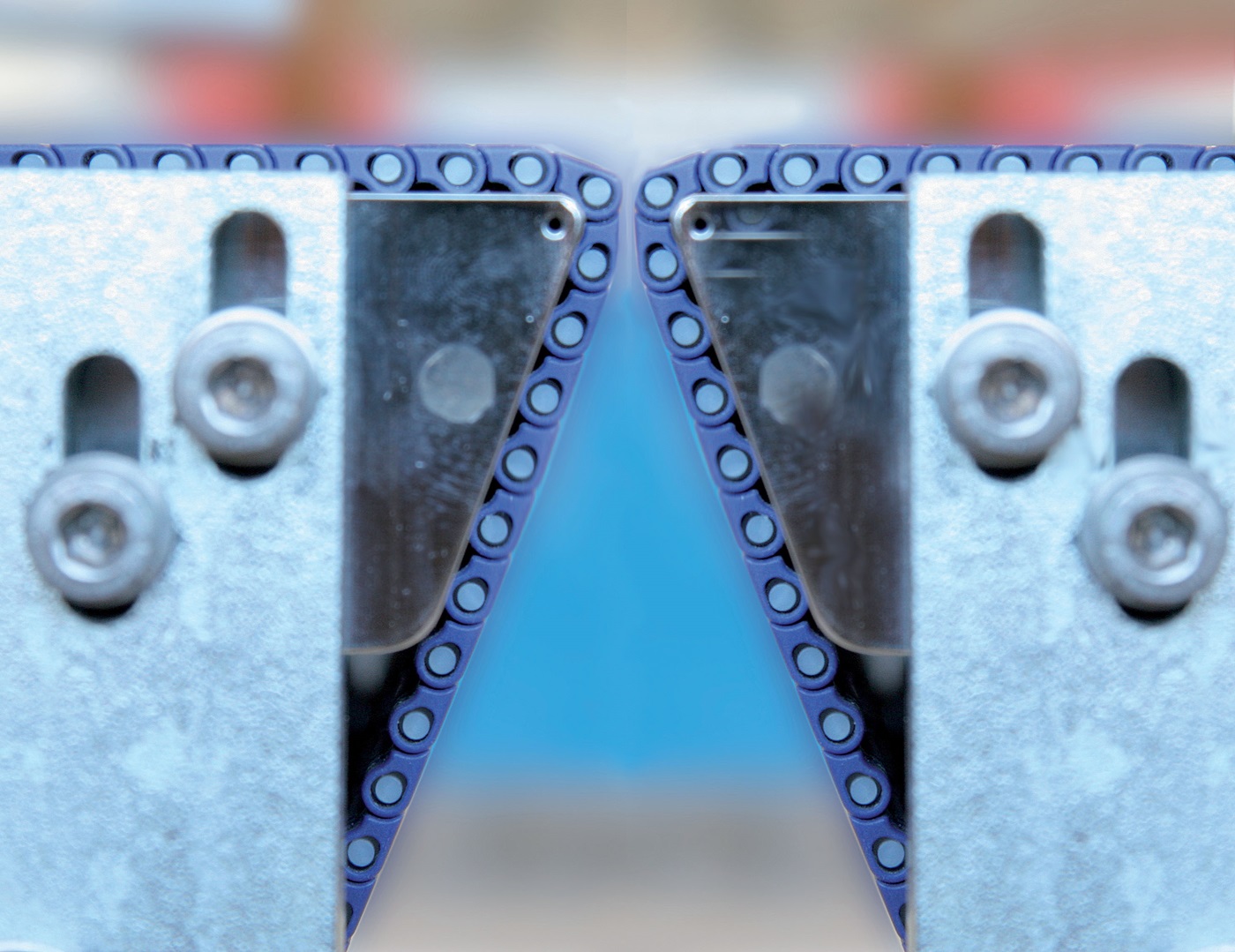

To successfully move the product without disengaging and damaging the sprockets, the company needed a belt that met the same transfer point requirements, but with a better load capability. Habasit solved the problem with HabasitLINK® M0870. With a 15% stronger rating, it satisfied the customer’s requirements while also providing deeper tooth engagement.

During the first year after installation, the M0870 belt performed all 12 months without any issues. That’s an additional 10.5 to 11 months of service compared to the competitor’s belt it replaced. Even better, the Habasit belt is still in operation, providing additional savings beyond just the first year. And, the company now knows how Habasit can help eliminate unscheduled downtime on their other production lines throughout their facilities.

Total savings: $8,471 in annual belt and installation costs for one line.