Habasitlink F51 Kynar Belt Material Stands Strong in Even the Most Extreme Conditions

An aluminum can washing facility experiences some tough conditions in their washing processes. In a wet environment of high temperatures and strong acidic chemical mixes, the standard conveyor belt just wasn’t holding up.

As such, they were seeing a significant decrease in belt life expectancy and premature failure due to severe material degradation. The competitor's belts would only provide 12-14 months of service before breaking down and causing costly, unexpected downtime.

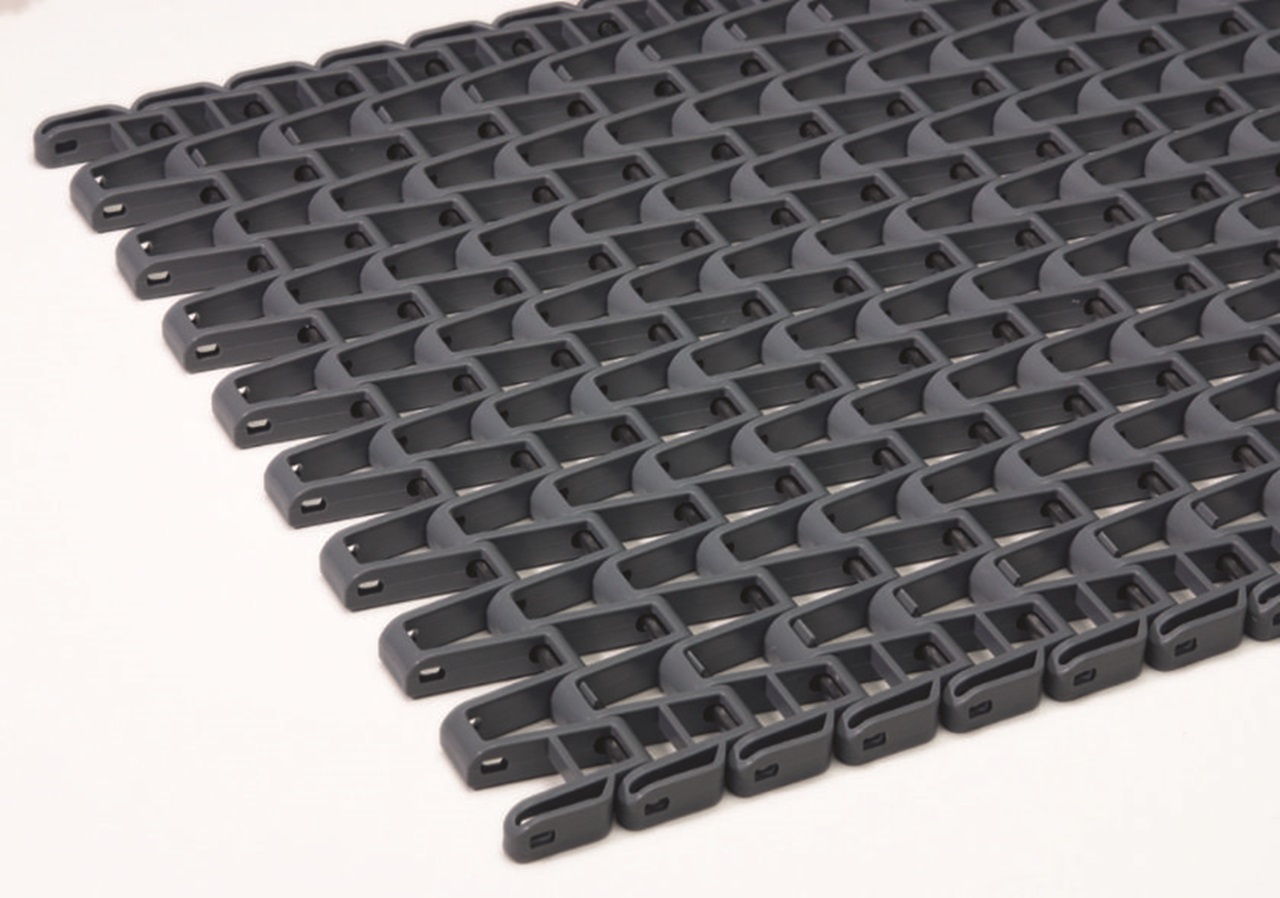

The company needed a belt with a much more durable construction that could withstand harsh conditions and chemical mixes without degrading. Habasit had the answer: a belt made of F51 Kynar material.

The chemical-resistant Kynar extended the belt life to four times the previous belt material. After four years of use, it still shows no signs of wear or degradation and the plant is already realizing significant savings in maintenance and downtime. With such excellent performance, the company was even able to add washing lines at more locations.

Results: $216,800 saved in maintenance costs and damage to cans.