Durable Edge Construction of CDT-139_18 Saves Bread Maker a Lot of Dough

As part of its baking process, a bread maker transfers dough from an extruder to a sheeter and then a panner. Due to frequent use, the competitor's fabric belt was fraying at the edges and extremely difficult to clean, compromising food quality and safety. Often, employees would have to stop the line to trim the entire length of the belt or call a service technician to come install a replacement belt – leaving the bread maker dealing with hours of unexpected downtime and a loss of valued productivity. The company realized a belt with durable edge construction would be much easier to clean and would not require outsourced help to service or install. Habasit had the perfect solution: CDT-139_18. This monolithic, reinforced conveyor belt is completely free of fabric, so there is absolutely no fraying during use. It’s made of a homogenous, thermoplastic polyurethane (TPU) material, resulting in a much easier cleaning process. The company can also keep additional belts in storage for its maintenance team to easily install when needed, ensuring maximum uptime for production.

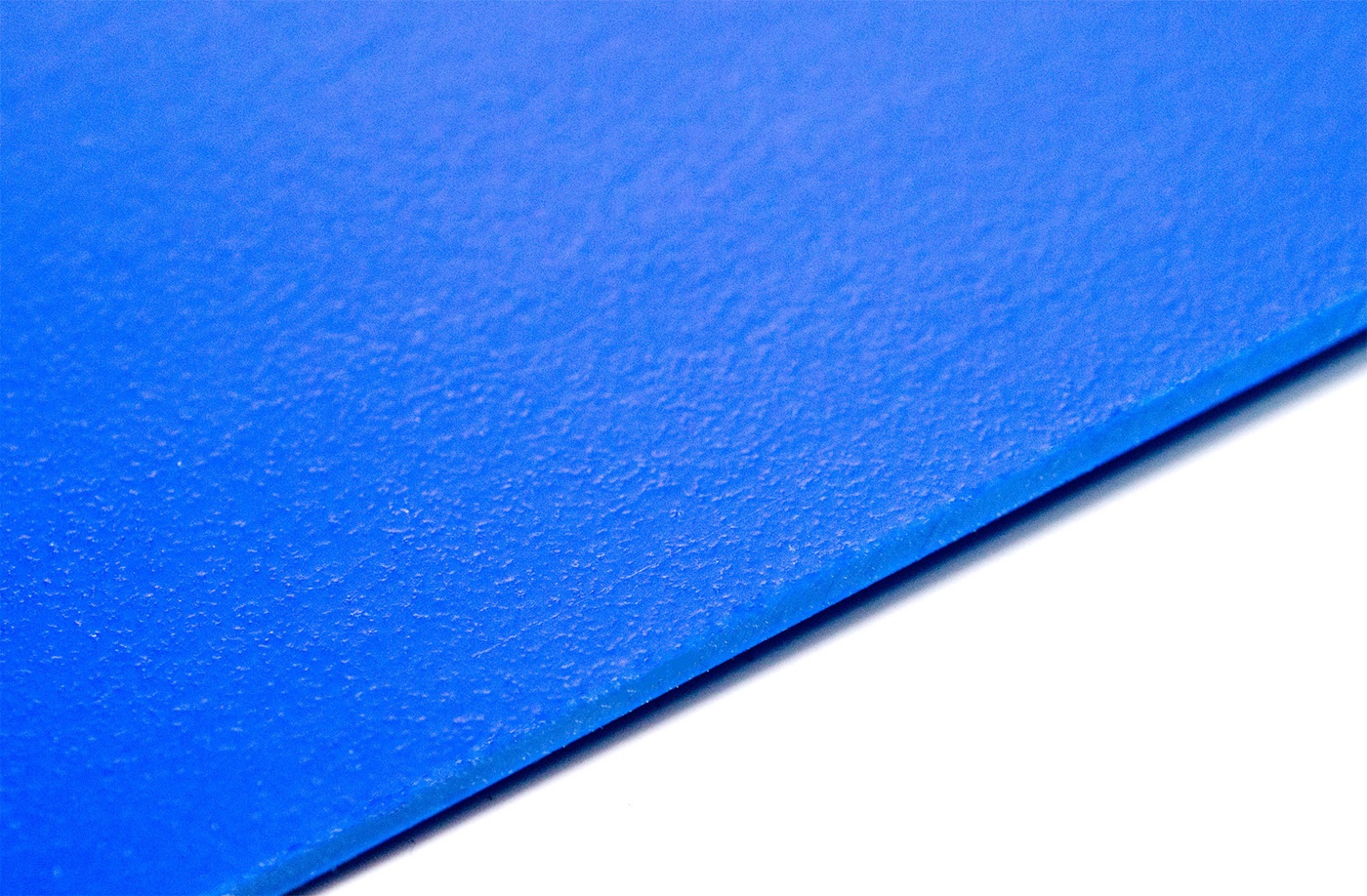

Additionally, one side of CDT-139_18 has a smooth adhesive surface and the other has an “orange peel” surface with a lower coefficient of friction, perfect for bakery applications.

Results: $85,000 annually in downtime, and belt maintenance, cleaning and installation savings.