M2533’s Unique Flush Grid Design Improves Support and Cuts Scrap

A manufacturer of hydrophilic foam had installed a competitor's flush grid belt to convey the foam through a microwave for dewatering. Though the competitor's belt would last many years, the flush grid module design was not optimal for the impressionable foam, retaining product from previous shifts and resulting in costly scrap and downtime. There were no benefits to be gained by a material change, so the customer required a superior overall design.

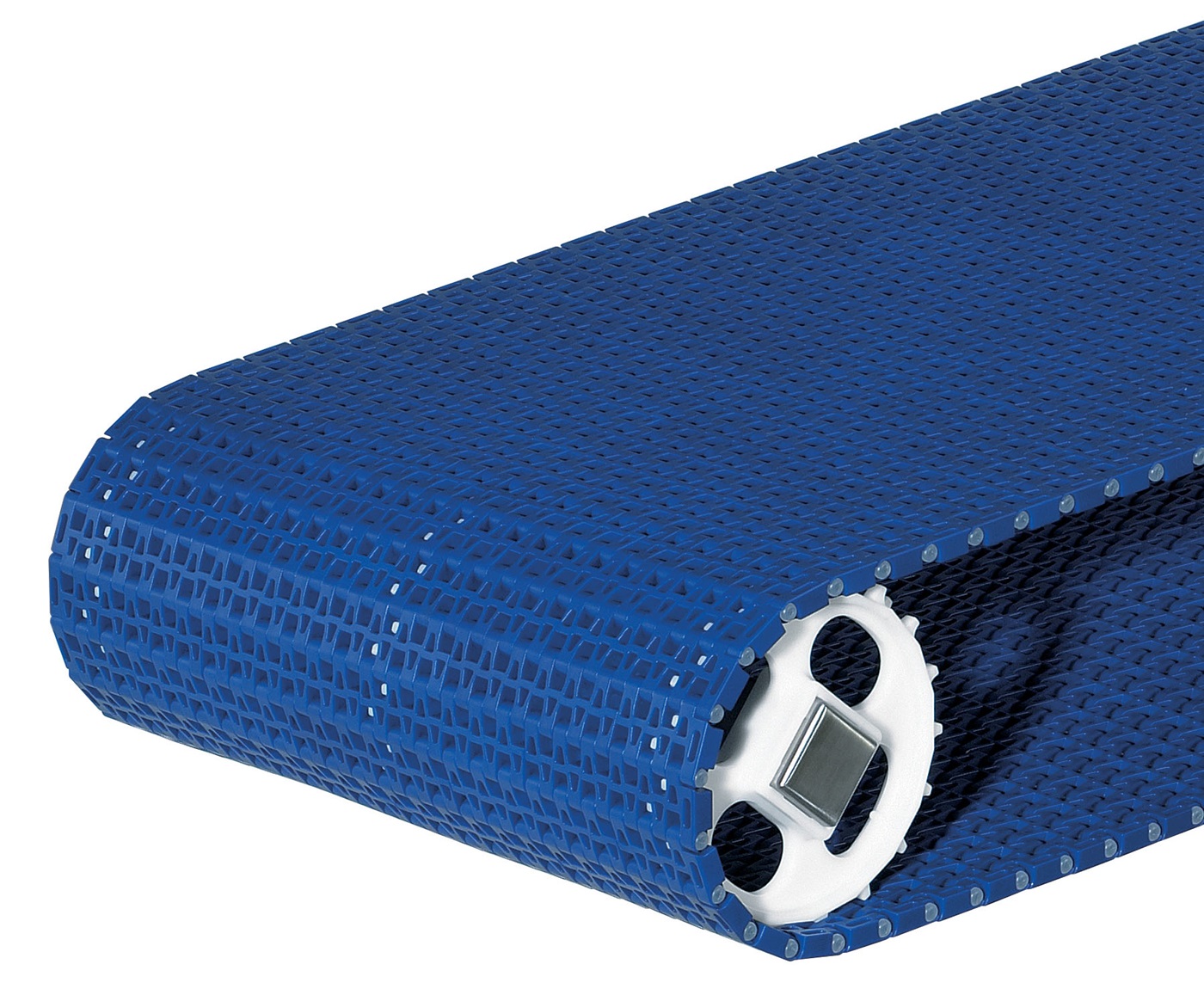

To eliminate the scrap retention, the manufacturer required a plastic modular belt suitable for use in a microwave and conducive to dewatering while offering improved product support and release. Habasit satisfied this requirement with the M2533 Flush Grid belt, featuring a truly unique design with robust lines and softer edges, achieving a 60% open contact area with a smooth surface.

When installed, the M2533 better supported the product and minimized foam retention, saving material and reducing downtime for cleaning.

Overall, the manufacturer enjoyed several benefits from the M2533's adoption:

- $52,500 in scrap saved annually

- $42,500 in reduced annual downtime

- Added value through competitive pricing

Total annual savings approached $100,000.

The M2533's stronger design ably accommodates longer conveying applications. The belt's open-hinged underside is highly cleanable, offering 26% rod exposure (higher than the competitors). The M2533 is an excellent case of genuinely superior design.