Oil Resistance and Frayless Design End Staining and Contamination

A snack producer making seasoned tortilla chips experienced regular product contamination from its standard 3-ply nitrile incline belt due to fraying of the belt's fabric members. The fraying was caused by a combination of oversized belt width, abrasive seasoning granules, and the effects of oil absorption on belt tracking. Also, the nitrile belt offered low cleanability, resulting in unsightly and unsanitary staining on the bottom fabric side due to oil presence. To eliminate the contamination, the customer required a flat, food-safe belt with a frayless construction, highly cleanable surface, and improved resistance to abrasion and oil absorption. Designed with no fabric layers, Habasit Cleandrive is a perfectly smooth monolithic style belt extruded in a premium TPU material that offers superior abrasion resistance and stain-blocking oil resistance. Having no pores or crevices to harbor foodstuff and featuring smooth rounded corners, Habasit Cleandrive represents one of the most cleanable belt designs available. Once installed, Habasit Cleandrive tracked reliably up the incline conveyor, without oil staining or product contamination from abrasion-related dusting and debris.

Overall, the snack producer enjoyed big benefits:

- 6:1 belt life improvement

- Reduced maintenance costs for replacements

- Easier sanitation due to high cleanability

Total annual savings reached $54,190.

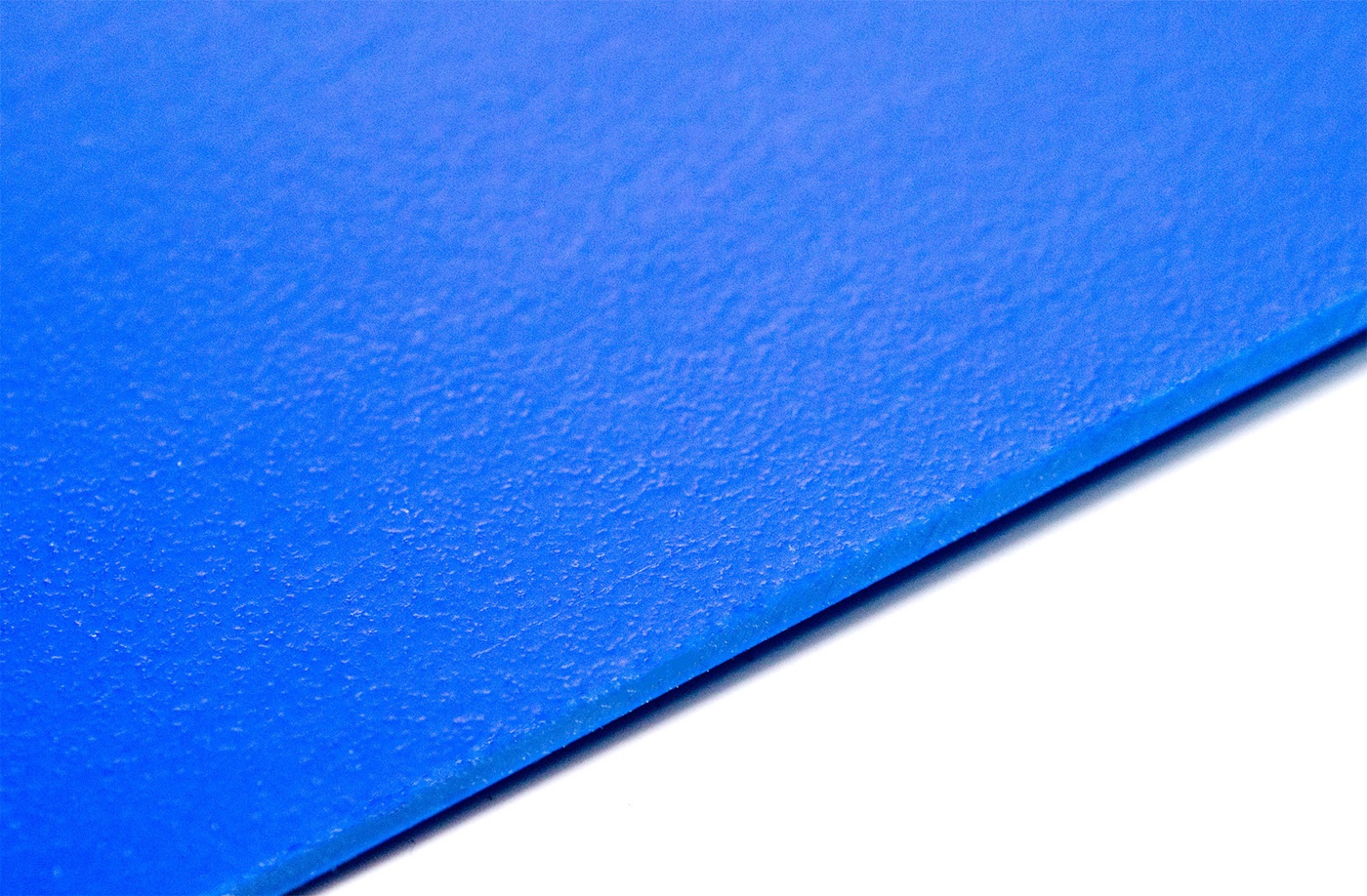

The Habasit sales representative recommended using Habasit Cleandrive with the Orange Peel cover. The textured cover was positioned to face the slider bed to minimize oil-related suction and enable smoother sliding up the incline.