Engineered for reliable operations and hassle-free maintenance

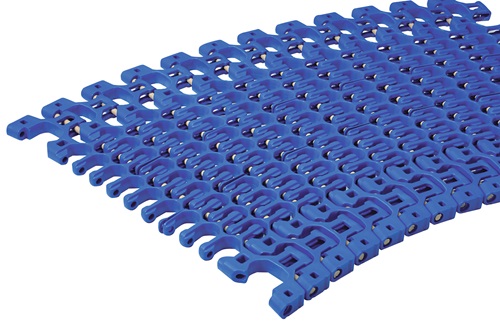

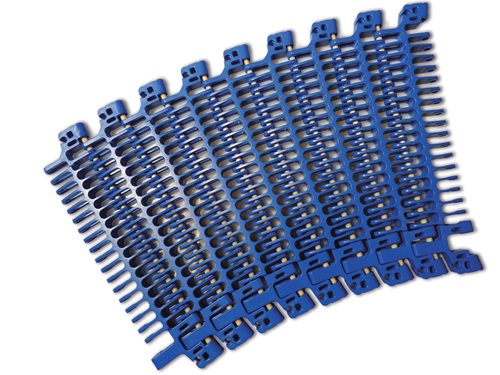

The HabasitLINK spiral belts deliver high airflow and their rounded surfaces prevent product marking. The range of solutions includes belts with multiple collapse factors to optimize the machine footprint and a wide material portfolio to handle the required temperature range.

Our spiral belts have been running in thousands of systems worldwide and are a proven technology used every day in a broad range of applications.

Retrofit or new installation? Think HabasitLINK!

Plastic modular belts offer a number of advantages over steel belts used in spiral conveyors:

- Prevent the risk of contamination of your products with metal belt wear debris and steel lubricant

- End stainless steel “blackening” of your products

- Boost product yield with non-stick FDA/USDA direct contact plastic belt surfaces

- Increase your product throughput thanks to the greater loading capacity of lighter and stronger belts

- Reduce spiral downtime through reduced system wear, lower belt tension, significantly less ice and frost build-up, and quick, thorough belt cleaning

- Cut back maintenance time:

- Reduce “run-in” time, reduce lubrication requirements, and eliminate the need for periodic belt ”flipping”

- End periodic wear strip and charge-bar cap replacement

- Eliminate steel belt cutting, grinding, and welding

Habasit SmartLINK

Spiral conveyors need to have belt tensile force surveyed continuously to monitor friction increments between the belt and wear strips support, which may be caused by missing or improper cleaning.

Smart Link is the real-time Habasit spiral conveyor belt monitoring system embedded into the belt that performs this task providing additional valuable data.

Downloads