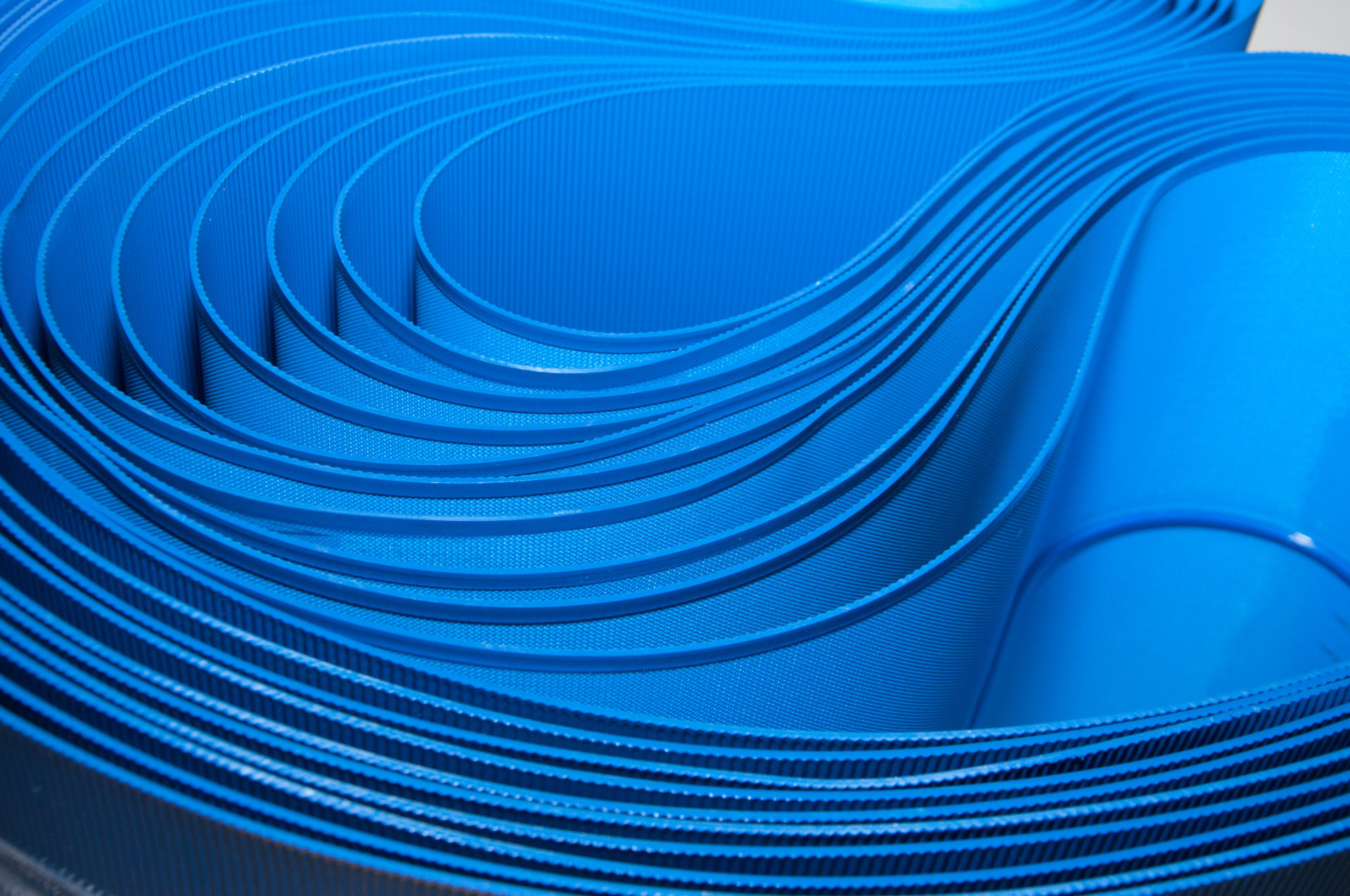

Reliable belts that get things moving

Habasit’s fully synthetic, high-quality power transmission belts are equipped with a strong and resilient traction layer made of polyamide, polyester, or aramid. Wear-, oil- and grease-resistant friction covers made of NBR rubber provide a high degree of consistent friction between belt and pulleys.

The versatility and energy-saving properties of these maintenance-free belts make them a key component in all areas of power transmission technology. Their long service life and little or no unexpected machine downtime make them a reliable solution across a variety of industries.

Product Types

Discover our power transmission belts

The Habasit portfolio includes polyester, polyamide, and aramid power transmission belts, customized to suit a wide array of machine designs.

Polyamide Power Transmission Belts

Aramid Power Transmission Belts

TF range belts are the best choice for very long belts in situations where high accuracy and consistent belt speeds are required. The belts’ advantages include a high modulus of elasticity that results in very high spindle revolution uniformity, no retensioning, low energy consumption, and a long service life.

Main features:

Main features:

- Symmetric belt construction, suitable for double-sided power transmission

- Low energy consumption

- Highly flexible

- Excellent reversed bending and flex-fatigue properties

- Very high accuracy of rpm thanks to a high modulus of elasticity

- Very short take-up

- Extremely compact driving configurations (serpentine drive)

- Suitable for high speeds

- Proven NBR rubber covers with high abrasion resistance

- Simple and fast to join (adhesive-free Flexproof method)

Browse the wide selection of Habasit belts, accessories and conveyor components

What's new?

Downloads